ISO 11197:1996

(Main)Medical electrical equipment — Particular requirements for safety of medical supply units

Medical electrical equipment — Particular requirements for safety of medical supply units

Applies to medical supply units as defined in 1.3.4 of ISO 11197. Other medical equipment, such as devices for nurse call systems, monitoring, etc., which can be incorporated in or mounted on medical supply units, are not covered by this International Standard. Such medical equipment may be the subject of additional Particular Standards.

Appareils électriques médicaux — Prescriptions particulières relatives à la sécurité des systèmes de distribution médicaux

General Information

Relations

Standards Content (Sample)

INTERNATIONAL

IS0

STANDARD

11197

First edition

1996-04-I 5

Medical electrical equipment - Particular

requirements for safety of medical supply

units

Appareils hlectriques m6dicaux - Prescriptions particukres relatives 8 la

s&wit6 des systkmes de distribution mgdicaux

Reference number

IS0 11197:1996(E)

---------------------- Page: 1 ----------------------

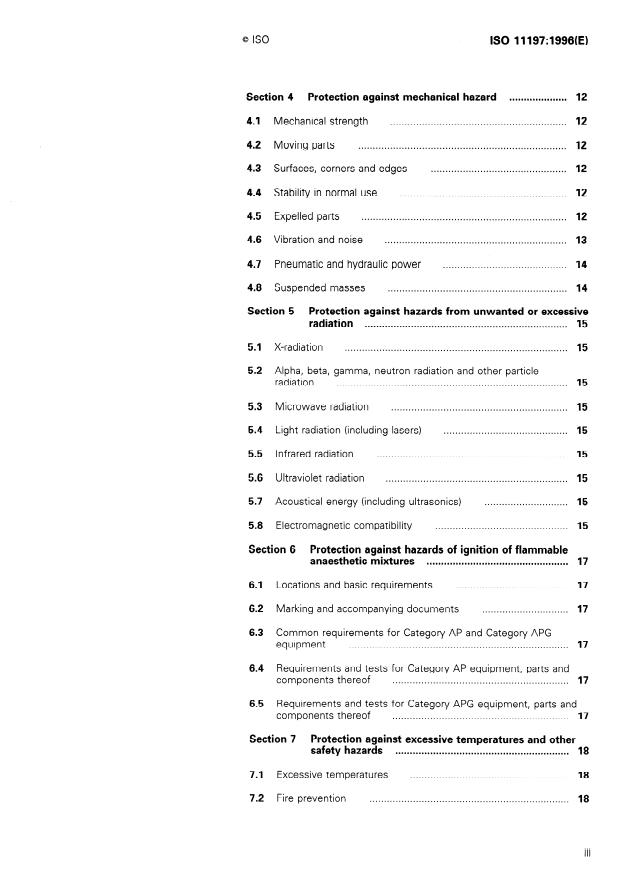

IS0 11197:1996(E)

Contents

Page

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Section 1 General

1

1.1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1.2 Normative references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Definitions

6

1.4 General requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 General requirements for tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7 Identification, marking and documents

1.8 Power input . . 9

Section 2 Environmental conditions . . . . . . . . . . . . . . . . . . . .s. 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Basic safety categories 10

2.2 Removable protective means . . 10

2.3 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . .* . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Special measures with respect to safety

2.5 Single fault condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . 11

Section 3 Protection against electric shock hazards

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Requirements related to classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Limitation of voltage and/or energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Enclosures and protective covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . 11

35 Separation .

3.6 Protective earthing, functional earthing and potential

equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*. 11

11

3.7 Continuous leakage currents and patient auxiliary currents

3.8 Dielectric strength . . 11

0 IS0 1996

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, rnciuding photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case Postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

ii

---------------------- Page: 2 ----------------------

0 IS0 IS0 11197:1996(E)

. . . . . . . . . .*.*. 12

Section 4 Protection against mechanical hazard

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Mechanical strength

4.2 Moving parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12

4.3 Surfaces, corners and edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

4.4 Stability in normal use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

4.5 Expelled parts *.

13

4.6 Vibration and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

4.7 Pneumatic and hydraulic power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.8 Suspended masses

Section 5 Protection against hazards from unwanted or excessive

radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

15

5.1 X-radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Alpha, beta, gamma, neutron radiation and other particle

15

radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Microwave radiation

5.4 Light radiation (including lasers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

15

5.5 Infrared radiation . . . . . . . . .*.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.6 Ultraviolet radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7 Acoustical energy (including ultrasonics)

5.8 Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Section 6 Protection against hazards of ignition of flammable

17

anaesthetic mixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*.

17

6.1 Locations and basic requirements . . . . . . . . . . . . . . . . . . . . . . . . . .*.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Marking and accompanying documents

6.3 Common requirements for Category AP and Category APG

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

equipment

6.4 Requirements and tests for Category AP equipment, parts and

components thereof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.5 Requirements and tests for Category APG equipment, parts and

components thereof . . . . . . .s. 17

Section 7 Protection against excessive temperatures and other

18

safety hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Excessive temperatures . . 18

7.2 Fire prevention . . 18

---------------------- Page: 3 ----------------------

IS0 11197:1996(E) 0 IS0

Overflow, spillage, leakage, humidity, ingress of liquids, cleaning,

73 .

sterilization and disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

74 . Pressure vessels and parts subject to pressure

. . . . . . . . . . . . . . . . . . 18

75 . Human errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

76 . Electrostatic charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

7.7 Material in applied parts in contact with the body of the

patient . . . . . . . . . . . . .*.*.

19

7.8 Interruption of the power supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Section 8 Accuracy of operating data and protection against

hazardous output . 20

Accuracy of operating data

8.1 . 20

8.2 Protection against hazardous output . 20

Section 9 Abnormal operation and fault conditions; environmental

tests .

21

9.1 Abnormal operation and fault conditions

............................. 21

9.2 Environmental tests

............................................................. 21

Section 10

Constructional requirements . 22

10.1 General . . 22

10.2 Enclosures and covers . 22

10.3 Components and general assembly . 22

10.4 Mains parts, components and layout .

22

10.5 Protective earthing - Terminals and connections . 22

10.6 Construction and layout . 24

Annexes

.............................................................................

M Bibliography 30

.................................................................................. 31

N Rationale

iv

---------------------- Page: 4 ----------------------

0 IS0

IS0 11197:1996(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work

of preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(I EC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting

a vote.

International Standard IS0 11197 was prepared by Technical Committee

ISO/TC 121, Anaesthetic and respiratory equipment, Subcommittee

SC 6, Medical gas systems.

Annexes M and N of this International Standard are for information only.

---------------------- Page: 5 ----------------------

This page intentionally left blank

---------------------- Page: 6 ----------------------

IS0 11197:1996(E)

INTERNATIONAL STANDARD 0 IS0

- Particular

Medical electrical equipment

requirements for safety of medical supply units

Section 1: General

1.1 Scope

IS0 11197 is one of a series of International Standards based on IEC 601-I; in IEC 601-I (the “General

Standard”), this type of International Standard is referred to as a “Particular Standard”. As stated in 1.3 of

IEC 601-I :1988, the requirements of this International Standard take precedence over those of IEC 601-I.

The scope and object given in clause 1 of IEC 601-I :I 988 apply, with the following addition:

This International Standard applies to medical supply units as defined in 1.3.4 of IS0 11197.

Other medical equipment, such as devices for nurse call systems, monitoring, etc., which can be incorporated in

or mounted on medical supply units, are not covered by this International Standard. Such medical equipment may

be the subject of additional Particular Standards.

1.2 Normative references

The following standards contain provisions which, through reference in this text, constitute provisions of this

International Standard. At the time of publication, the editions indicated were valid. All standards are subject to

revision, and parties to agreements based on this International Standard are encouraged to investigate the possi-

bility of applying the most recent editions of the standards indicated below. Members of IEC and IS0 maintain

registers of currently valid International Standards.

- Marking for identification of content.

IS0 32:1977, Gas cylinders for medical use

IS0 3744:1994, Acoustics - Determination of sound power levels of noise sources using sound pressure - En-

gineering method in an essentially free field over a reflecting plane.

IS0 5359:1989, low-pressure flexible connecting assemblies (hose assemblies) for use with medical gas

systems.

IS0 7396: 1987, Non-flammable medical gas pipeline systems.

IS0 9170:1990, Terminal units for use in medical gas pipeline systems.

I EC 79-4: 1975, EiectricaI apparatus for explosive gas atmospheres - Part 4: Method of test for ignition tem-

perature.

- Part I: General requirements and tests.

I EC 598-l : 1992, Luminaires

---------------------- Page: 7 ----------------------

Q IS0

IS0 11197:1996(E)

I EC 601-I : 1988, Medical electrical equipment - Part 7: General requirements for safety.

- Part 1: Genera/ requirements for safety. I. Collatera I standard:

I EC 601-I -1: 1992, Medical electrica/ equipment

Safety requirements for medical electrical systems.

I standard:

I EC 601-I -2: 1993, Medical electrical equipment - Part 1: General requirements for safety. 2. Co/la tera

Electromagnetic compatibility - Requirements and tests.

IEC 884-l :I 994, Plugs and socket-outlets for household and similar purposes - Part 1: General requirements.

1.3 Definitions

I EC 601-I:1988 and the fol-

For the purposes of this International Standard, the definitions given in clause 2 of

lowing definitions apply.

1.3.1 equipment: Single self-contained unit or combination of units provided with one or more permanently fixed

connections to the building services, e.g. electrical, gas(es), liquid and anaesthetic gas scavenging systems.

NOTE I This definition replaces the definition of equipment given in 2.21 I of IEC 6014 :1988.

1.3.2 junction point: Connection point between the medical supply unit and the fixed building services.

1.3.3 medical gas: Any gas or mixture of gases intended to be administered to patients for therapeutic, diag-

nostic or prophylactic purposes, or for surgical tool application.

1.3.4 medical supply unit: Prefabricated equipment of Class I, Type B for application in medical areas such as

general wards and special purpose areas (e.g. operating theatres, induction rooms, recovery wards, intensive care

or therapy units and other intermediate care areas) that is intended to supply electric power and/or gases and/or

liquids.

NOTE 2 Medical supply units may include medical electrical equipment or systems or parts of such equipment or systems

which might be applied to diagnosis, therapeutics and communications. Medical supply units may consist of modular sections

for electrical supply, lighting for therapy or illumination for communications for the supply of medical gases and liquids and for

anaesthetic gas scavenging systems. Typical examples of medical supply units are given in figures 1, 2 and 3.

1.3.5 oxidizing medical gas: Oxygen, nitrous oxide or gas mixtures in which the total concentration of oxygen

25 % volume fraction.

and nitrous oxide exceeds

2

---------------------- Page: 8 ----------------------

IS0 11197:1996(E)

1

r

_a_----------

6

\ L-

9 8

I Ambient lighting fitting

2 Electrical socket

3 Mains supply

4 Intercommunication, safety extra-low voltage

5 Recessed equipment

6 Barrier

7 Terminal unit

8 Pipeline installation

9 Reading light

Safety distance as distance from centre to centre = 0,2 m

IO

- Sectional drawing of typical medical supply unit for patient care rooms

Figure 1

---------------------- Page: 9 ----------------------

IS0 11197:1996(E)

I

---

OoO I

I

----J

L

*

-----

1

o”o ; t

l------ ----

--~_ t

6

1 Electrical socket

2 Mains supply

3 Intercommunication, safety extra-low voltage

4 Recessed equipment

5 Barrier

6 Terminal unit

7 Pipeline installation

8 Safety distance as distance from centre to centre = 0,2 m

Figure 2 - Sectional drawing of typical medical supply unit for intensive care rooms and operating

theatres

---------------------- Page: 10 ----------------------

IS0 11197:1996(E)

_--mm-----

6

------

7

8

1 Barrier

2 lermlnal units

3 Recessed equipment, low current electroinstallation, intercommunication safety extra-low voltage

4 Electrical socket

5 Safety distance measured on the surface as distance from centre to centre = 0,2 m

6 Flexible hoses

7 Mains installation

8 Low current installation

Figure 3 - Sectional drawing of typical non-rigid medical supply unit

---------------------- Page: 11 ----------------------

IS0 11197:1996(E)

1.4 General requirements

The requirements given in clause 3 of IEC 601-I :I 988 apply with the following addition:

- To 3.6 add the following:

k) An oxidant leak which remains undetected shall be considered a normal condition and not a single-fault

condition.

lis subclause is provided in annex N.

A rationale for t

1.5 Genera I requirements for tests

The requirements given in clause 4 of IEC 601-I :I 988 apply.

1.6 Classification

The requirements given in clause 5 of IEC 601-I :I 988 apply.

1.7 Identification, marking and documents

The requirements given in clause 6 of IEC 601-I :I 988 apply with the following amendments:

- Replace 6.1 a) with the following:

Mains-operated equipment, including separable components thereof which have a mains part, shall be

provided at least with permanently affixed and clearly legible marking on the outside of the major part of

the equipment as described in 6.1 c).

- Replace 6.1 g) with the following:

Due to the possible complexity of external marking, diagrams indicating all electrical and electronic con-

nections to the medical supply units shall be located at the junction point inside the equipment. For electrical

connections the diagram shall indicate voltages, number of phases and number of circuits. For electronic

connections, the diagram shall indicate connector numbers and wire identification.

- Replace 6.1 k) with the following:

Mains socket outlets for special-purpose areas should be colour-coded according to national regulations of

NOTE -

the nation where the equipment is to be installed. Mains socket outlets for special-purpose areas which are fused in

a single circuit may be marked with identical numbers.

- Under 6.1 I), replace text after third dash with the following:

Medical supply units shall be designed and constructed as Class I, Type B equipment according to the de-

gree of protection against electric shock. A marking for this degree of protection is not required. Built-in

units of Type BF or CF and outlets forming part of them, contained in medical supply units, shall be clearly

marked with the relevant symbols according to Appendix D, Table D II.

- To 6.1 y) add the following:

Facilities for the connection of a potential equalization conductor, if provided, shall be marked with

symbol 9 of Table D I of Appendix D.

---------------------- Page: 12 ----------------------

0 IS0

IS0 11197:1996(E)

- After 6.1 z), add the following:

aa) Particular applications

If the medical supply unit is intended to be used in conjunction with patient monitors, for electromyogram

and/or electroencephalogram and/or electrocardiogram, the medical supply unit shall be marked with the

particular application as follows:

l for electromyogram EMG

l for electroencephalogram EEG

l for electrocardiogram ECG or EKG

bb) Terminal units

Terminal units for medical gases shall be marked in accordance with IS0 9170:1990, clause 6. Colour cod-

ing, if used, shall be in accordance with IS0 32.

An International Standard covering the marking of terminal units for anaesthetic gas scavenging equipment

is under development.

Terminal units for liquids shall be marked with the name of the liquid in accordance with table 1 or the na-

tional equivalent.

Colour coding, if used, shall be in accordance with national standards.

Table 1 - Names of liquids for marking of

terminal units

Potable water, COLD

I I

Potable water, WARM

I I

1 Cooling water

~~

Cooling water, feedback

I I

Demineralized water

I I

Distilled water

I I

1 Dialysing concentrate

I

I Dialysing permeate

- To 6.2, add the following:

o) Junction points and pipelines for medical gases shall be marked in accordance with IS0 7396:1987,

clause IO.

p) Junction points and pipelines for liquids shall be marked with

l the name of the liquid in accordance with table I;

l the direction of flow;

l (optionally) colour coding in accordance with national standards.

q) An International Standard covering the marking of junction points and pipelines for anaesthetic gas

scavenging systems is under development.

7

---------------------- Page: 13 ----------------------

0 IS0

IS0 11197:1996(E)

- To 6.8.1, add the following:

The accompanying documents for medical supply units shall certify that all tests have been completed and

that the medical supply unit complies with all requirements of this standard when the manufacturing is

completed.

- To 6.8.2a), add the following:

l Instructions for use shall state which parts of equipment are capable of bearing additional loads. The maxi-

mum allowable load shall be stated.

l Instructions for use relating to cleaning and inspection shall indicate to the owner or operator the hazard that

may arise from accumulating flammable material such as lint within the unit, and the risk of using flammable

cleaning agents in the presence of electrical outlets.

l If flexible hoses and hose assemblies are used for medical gas supply, anaesthetic gas scavenging and

liquid supply for operator-adjustable systems, e.g. ceiling pendants, the instruction for use shall include a

procedure for, and the frequency of, inspection and replacement.

l If flexible hoses are used for medical gas supply for operator-adjustable systems, e.g. ceiling pendants, the

instruction for use shall state that the following tests shall be carried out in accordance with IS0 5359 fol-

lowing modification or replacement of the flexible hose:

I) test for leakage;

2) test for obstruction;

test for particulate contamination;

3)

4) test of gas identity.

If flexible hoses are used for anaesthetic gas scavenging for operator-adjustable systems, e.g. ceiling pen-

l

dants, the instruction for use shall state that the following tests shall be carried out in accordance with

IS0 5359 following modification or replacement of the flexible hose:

I) test for leakage;

test of flow and pressure drop.

2)

l If flexible hoses are used for liquid supply for operator-adjustable systems, e.g. ceiling pendants, the in-

struction for use shall state that a test for leakage shall be carried out following modification or replacement

of the flexible hose.

- Replace 6.8.2 b) with the following:

The manufacturer/supplier shall provide certification that the following production tests have been per-

formed for each unit and that the specified requirements are met:

i) protective earthing in accordance with 18f)

ii) earth leakage current in accordance with 19.3 and 19.4

iii) in accordance with 59.5 and/or 59.6 and/or 59.7.

- To 6.8.2j), add the following:

Medical supply units shall be installed and used in accordance with the following additional specifications:

l IEC Standard for electrical installation of hospitals and medically used rooms outside of hospitals (under

consideration). Until this IEC Standard is completed, relevant national standards shall apply.

---------------------- Page: 14 ----------------------

0 IS0 IS0 11197:1996(E)

l IS0 7396:1987

- To 6.8.3, add the following:

e) Disclosure by the manufacturer

- The manufacturer shall provide certification that the noise levels of clause 26 are not exceeded.

- The manufacturer shall submit upon request certification of the residual hydrocarbon content on the

inner surface of the medical gas pipes.

NOTE - The maximum permissible level of residual hydrocarbon content on the inner surface of the medical gas pipe

is under consideration by ISOPC 121 and CEN/TC 133.

1.8 Power input

The requirements given in clause 7 of IEC 601-I :I 988 apply.

---------------------- Page: 15 ----------------------

IS0 11197:1996(E)

Section 2: Environmental conditions

2.1 Basic safety categories

Appendix A. 1.2 of IEC 601-I :I 988 applies.

2.2 Removable protective means

[Not used; replaced by subclause 6.1 z).]

2.3 Environmental conditions

The requirements given in clause 10 of IEC 601-I :I 988 apply.

2.4 Special measures with respect to safety

(Not used.)

2.5 Single fault condition

(Not used; transferred to subclause 3.6.)

10

---------------------- Page: 16 ----------------------

IS0 11197:1996(E)

Protection against electric shock hazards

Section 3:

3.1 General

The requirements given in clause 13 of IEC 601-I :I 988 apply, with the following addition:

Luminaires (lighting fixtures), built in or mounted on medical supply units shall comply with IEC 598-l.

3.2 Requirements related to classification

The requirements given in clause 14 of IEC 601-I :I 988 apply.

3.3 Limitation of voltage and/or energy

The requirements given in clause 15 of IEC 601-I :I 988 apply.

3.4 Enclosures and protective covers

The requirements given in clause 16 of IEC 601-I :I 988 apply.

3.5 Separation

The requirements given in clause 17 of IEC 601-I :I 988 apply.

3.6 Protective earthing, functional earthing and potential equalization

The requirements given in clause 18 of IEC 601-I :I 988 apply, with the following addition:

m) Terminal units for medical gases and for anaesthetic gas scavenging systems are not required to be con-

nected to the earth terminal.

n) All earth conductors of circuits from the existing mains supply shall be connected in the medical supply

unit with a bus bar.

3.7 Continuous leakage currents and patient auxiliary currents

The requirements given in clause 19 of IEC 601-I :I988 apply, with the following addition:

- To Table IV, Note 3, add:

0 Medical supply units.

3.8 Dielectric strength

The requirements given in clause 20 of IEC 601-I :I 988 apply.

11

---------------------- Page: 17 ----------------------

IS0 11197:1996(E)

Section 4: Protection against mechanical hazard

4.1 Mechanical strength

The requirements given in clause 21 of IEC 601-I :I 988 apply, with the following addition:

21.7 Dynamic or static forces

In normal use, medical supply units may be subject to certain dynamic or static forces. The medical supply unit

shall be so designed that the safe function of the unit cannot be impaired by those forces. This requirement

is considered to be complied with if the medical supply unit meets the following tests:

a) A bag of width 0,5 m approximately half-filled with sand to give a total weight of 200 N and suspended so

as to give a pendulum length of 1 m, shall be released from a horizontal deflection of 0,5 m so as to hit the

medical supply unit, mounted according to the manufacturer’s instructions. The test configuration is shown

in figure4. After the impact, the live parts shall not become accessible, terminal units shall not mechanically

malfunction or leak, and existing protective devices shall remain intact.

NOTE - The occurrence of cracks in mouldings does not constitute failure of the test.

b) Static-load test sections of the medical supply unit designed for additional loads shall be subjected to a test

load of twice the safe working load specified by the manufacturer. The test load shall be uniformly dis-

tributed over the medical supply unit according to the manufacturer’s specifications. The medical supply

unit and its section designed for additional loads shall not be permanently deformed nor deflect by more

than IO” against the non-load-bearing surfaces.

4.2 Moving parts

The requirements given in clause 22 of IEC 601-I :I 988 apply.

4.3 Surfaces, corners and edges

The requirements given in clause 23 of IEC 601-I :I 988 apply.

4.4 Stability in normal use

The requirements given in clause 24 of IEC 601-I :I 988 apply.

4.5 Expelled parts

The requirements given in clause 25 of IEC 601-I :I 988 apply.

12

---------------------- Page: 18 ----------------------

IS0 11197:1996(E)

\- OSm -1

i

3 4

1 Length of pendulum

2 Deflection

3 Mounted medical supply unit

4 Most vulnerable point (example)

5 Bag of weight 200 N

Figure 4 - Impact resistance test

4.6 Vibration and noise

The requirements given in clause 26 of IEC 601-I :I 988 apply, together with the following requirement:

Except for noise caused by therapeutic or diagnostic measures or by adjustment of the medical supply unit (e.g.

by l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.