ISO 7396-2:2000

(Main)Medical gas pipeline systems — Part 2: Anaesthetic gas scavenging disposal systems

Medical gas pipeline systems — Part 2: Anaesthetic gas scavenging disposal systems

Réseaux de distribution de gaz médicaux — Partie 2: Systèmes d'évacuation de gaz d'anesthésie non réutilisables

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7396-2

First edition

2000-11-15

Medical gas pipeline systems —

Part 2:

Anaesthetic gas scavenging disposal

systems

Réseaux de distribution de gaz médicaux —

Partie 2: Systèmes d'évacuation de gaz d'anesthésie non réutilisables

Reference number

ISO 7396-2:2000(E)

©

ISO 2000

---------------------- Page: 1 ----------------------

ISO 7396-2:2000(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2000

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2000 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 7396-2:2000(E)

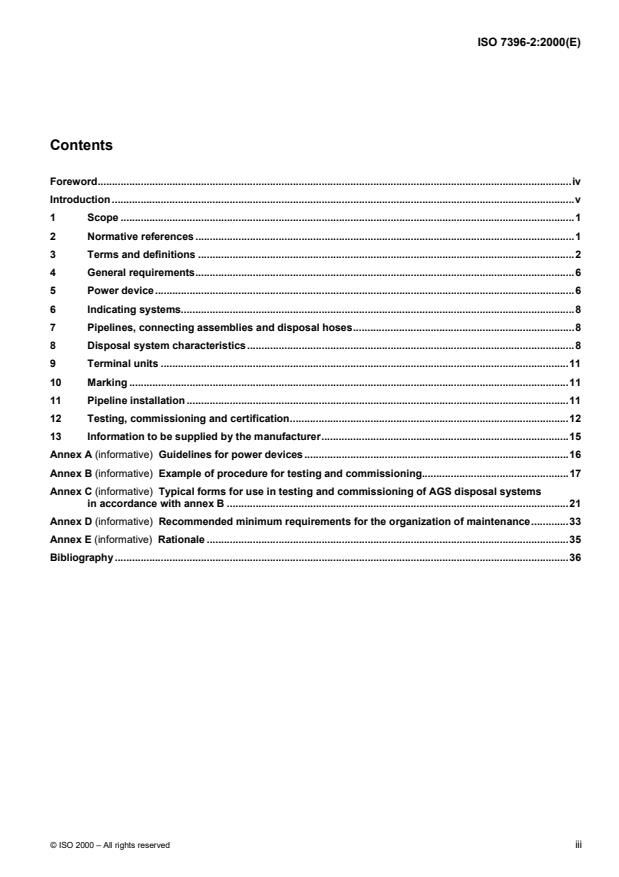

Contents

Foreword.iv

Introduction.v

1 Scope .1

2 Normative references .1

3 Terms and definitions .2

4 General requirements.6

5 Power device.6

6 Indicating systems.8

7 Pipelines, connecting assemblies and disposal hoses.8

8 Disposal system characteristics.8

9 Terminal units .11

10 Marking .11

11 Pipeline installation .11

12 Testing, commissioning and certification.12

13 Information to be supplied by the manufacturer.15

Annex A (informative) Guidelines for power devices.16

Annex B (informative) Example of procedure for testing and commissioning.17

Annex C (informative) Typical forms for use in testing and commissioning of AGS disposal systems

in accordance with annex B .21

Annex D (informative) Recommended minimum requirements for the organization of maintenance.33

Annex E (informative) Rationale .35

Bibliography.36

© ISO 2000 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 7396-2:2000(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this part of ISO 7396 may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 7396-2 was prepared by Technical Committee ISO/TC 121, Anaesthetic and respiratory

equipment, Subcommittee SC 6, Medical gas systems.

ISO 7396 consists of the following parts, under the general title Medical gas pipeline systems:

� Part 1: Pipelines for compressed medical gases and vacuum

� Part 2: Anaesthetic gas scavenging disposal systems.

Annexes A to E of this part of ISO 7396 are for information only.

NOTE Throughout this part of ISO 7396, a clause for which a rationale is provided in annex B is indicated by a boldface

capital R.

iv © ISO 2000 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 7396-2:2000(E)

Introduction

This part of ISO 7396 specifies requirements for anaesthetic gas scavenging (AGS) disposal systems.

The anaesthetic gas scavenging system (AGSS) comprises three main parts: a transfer system, a receiving system

and a disposal system. A schematic diagram of typical anaesthetic gas scavenging systems is shown in Figure 1.

Requirements for receiving systems and transfer systems are specified in ISO 8835-3. Type-specific connections for

terminal units are specified in ISO 9170-2. In this part of ISO 7396 specifications and test procedures are given to

ensure compatibility between the components of the system.

© ISO 2000 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 7396-2:2000(E)

Medical gas pipeline systems —

Part 2:

Anaesthetic gas scavenging disposal systems

1 Scope

This part of ISO 7396 specifies requirements for the installation, function, performance, documentation, testing and

commissioning of anaesthetic gas scavenging disposal systems to ensure patient and operator safety. It includes

requirements for the power device, pipeline system, performance and for non-interchangeability between key

components.

This part of ISO 7396 specifies:

a) the compatibility between and safe performance of the disposal system and the other components of the

AGSS by design, installation and commissioning;

b) the use of appropriate materials;

c) the testing for correct installation of the completed system to ensure achievement of the performance intended

by the manufacturer;

d) the marking of pipeline and components.

NOTE In this part of ISO 7396, the term “pipeline” refers exclusively to pipelines that are part of a dedicated anaesthetic

gas scavenging system.

This part of ISO 7396 is applicable only to those disposal systems which are intended to be connected via AGSS

terminal units which comply with ISO 9170-2 to receiving systems which comply with ISO 8835-3.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this part of ISO 7936. For dated references, subsequent amendments to, or revisions of, any of these publications

do not apply. However, parties to agreements based on this part of ISO 7936 are encouraged to investigate the

possibility of applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of ISO and IEC maintain

registers of currently valid International Standards.

ISO 5359, Low-pressure hose assemblies for use with medical gases.

ISO 7396-1, Medical gas pipeline systems — Part 1: Pipelines for compressed medical gases and vacuum.

ISO 8835-3:1997, Inhalational anaesthesia systems — Part 3: Anaesthetic gas scavenging systems — Transfer

and receiving systems.

ISO 9170-2, Terminal units for medical gas pipeline systems — Part 2: Terminal units for anaesthetic gas

scavenging systems.

© ISO 2000 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 7396-2:2000(E)

ISO 14971, Medical devices — Application of risk management to medical devices.

ISO 15001, Anaesthetic and respiratory equipment — Compatibility with oxygen.

3 Terms and definitions

For the purposes of this part of ISO 7936, the following terms and definitions apply.

3.1

AGSS socket

that female part of a terminal unit which is either integral or attached to the base block by a type-specific interface,

and which contains the type-specific connection point

3.2

AGSS terminal unit

inlet assembly in an AGS system at which the operator makes connections and disconnections

3.3

AGSS terminal unit base block

that part of an AGSS terminal unit which is attached to the pipeline disposal system

3.4

AGSS type 1 terminal unit

connection point between the receiving system and disposal system at which an operator makes connections and

disconnections

3.5

AGSS type 1L terminal unit

terminal unit to be used in low-flow disposal systems

3.6

AGSS type 1H terminal unit

terminal unit to be used in high-flow disposal systems

3.7

AGSS type 2 terminal unit

connection point between the power device or the disposal hose and the remainder of the disposal system at which an

operator makes connections and disconnections

3.8

AGSS type-specific

having characteristics which prevent interchangeability and thereby allow assignment to one AGSS type only

3.9

AGSS type-specific connection point

that part of the AGSS socket which is the receptor for an AGSS type-specific probe

3.10

air compressor system

source of supply with compressor(s) designed to provide air for breathing and/or air for driving surgical tools

3.11

anaesthetic gas scavenging system

AGSS

complete system which is connected to the exhaust port(s) of a breathing system or other equipment for the purpose of

conveying expired and/or excess anaesthetic gases to an appropriate place of discharge

2 © ISO 2000 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 7396-2:2000(E)

NOTE Functionally, an AGSS comprises three different parts: a transfer system, a receiving system and a disposal system.

These three functionally discrete parts may be either separate or sequentially combined in part or in total. In addition, one or

more parts of an AGSS may be combined with a breathing system or other equipment .

3.12

commissioning

proof of function to verify that an agreed specification is met and is accepted by the user or the representative of the

user

3.13

design capacity

total flow of an AGS disposal system taking into account the diversity factor, i.e. the number of AGSS terminal units

which may be in use at the same time

3.14

disposal hose

that part of an AGSS which transfers expired and/or excess gases from the power device to the probe of an AGSS

type 2 terminal unit

3.15

disposal system

means by which the expired and/or excess anaesthetic gases are conveyed from the receiving system to an

appropriate place of discharge

NOTE A place of discharge may be, for example, the exterior of a building or a non-recirculating extract ventilation system.

3.16

high-flow disposal system

disposal system that generates extract flows not lower than 75 l/min from transfer and receiving systems complying

with ISO 8835-3

3.17

low-flow disposal system

disposal system that generates extract flows not more than 50 l/min from transfer and receiving systems complying

with ISO 8835-3

3.18

manufacturer

natural or legal person with responsibility for the design, manufacture, packaging and labelling of a device before it

is placed on the market under his own name, regardless of whether these operations are carried out by that person

himself or on his behalf by a third party

3.19

maximum operating pressure

maximum pressure at which a terminal unit is designed to operate

NOTE Operating pressure for a type 1 terminal unit is negative, and for a type 2 terminal unit it is positive.

3.20

maximum test pressure

maximum pressure to which a terminal unit is designed to be subjected during pipeline pressure testing

3.21

non-return valve

valve which permits flow in one direction only

3.22

placing on the market

making available for the first time, in return for payment or free of charge, a device other than a device intended for

clinical investigation, with a view to distribution and/or use

© ISO 2000 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 7396-2:2000(E)

3.23

power device

that part of a disposal system of an AGSS which provides the gas flow for scavenging

3.24

probe

non-interchangeable male component designed for acceptance by, and retention in, a socket

3.25

quick-connector

pair of type-specific components which can be easily and rapidly joined together by a single action of one or both hands

without the use of tools

3.26

receiving hose

that part of an AGSS which transfers expired and/or excess gases from the receiving system to the disposal system

3.27

receiving system

that part of an AGSS which provides an interface between the transfer system and the disposal system

3.28

shut-off valve, isolating valve

manual or automatic valve which prevents flow in both directions when closed

3.29

single fault condition

condition in which a single means for protection against a safety hazard in equipment is defective or a single external

abnormal condition is present

3.30

terminal unit check valve

valve which remains closed until opened by insertion of an appropriate probe and which then permits flow in either

direction

3.31

transfer system

that part of an AGSS which transfers expired and/or excess anaesthetic gases from the exhaust port of the breathing

system to the receiving system

3.32

transfer tube

that part of an AGSS which transfers expired and/or excess gases from the breathing system to the receiving system

4 © ISO 2000 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 7396-2:2000(E)

Key

1 Apparatus including breathing system and integral transfer/receiving system 12 Discharge

and power device

13 Flexible hose or pendant

2 Apparatus including breathing system

14 Disposal hose

3 Transfer/receiving system and power device

15 Limit of breathing system

4 Apparatus including breathing system and integral transfer/receiving system

16 Limit of transfer system

5 Permanent or proprietary connector

17 Limit of receiving system

6 Receiving hose

18 Limit of disposal system

7 Breathing system or anaesthetic ventilator

19 Proprietary connection (functionally

8 Transfer tube specific)

9 Receiving system 20 30 mm conical connection

10 Power device 21 Type 1 terminal unit probe/socket

11 Permanent connection 22 Type 2 terminal unit probe/socket

NOTE 1 Type 1 terminal unit probe/socket is for negative pressure. Type 2 terminal unit probe/socket is for positive pressure.

NOTE 2 The limit between the receiving system and the disposal system as shown may not coincide with an actual physical

limit such as a wall.

Figure 1 — Schematic diagram of typical AGSS connections

© ISO 2000 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 7396-2:2000(E)

4 General requirements

4.1 Safety

AGS disposal systems shall, when installed, commissioned, operated in normal use and maintained according to

the instructions of the manufacturer, cause no safety hazard which could be foreseen using risk analysis

procedures in accordance with ISO 14971 and which is connected with their intended application, in normal

condition and in single fault condition.

4.2 R Alternative construction

AGS disposal system installations and components or parts thereof, using materials or having forms of construction

different from those detailed in this part of ISO 7396, shall be accepted if it can be demonstrated that an equivalent

degree of safety is obtained.

Such evidence shall be provided by the manufacturer.

4.3 Materials

4.3.1 The materials used for pipelines and other components of the disposal system shall be corrosion resistant

and compatible with anaesthetic gases and vapours under the operating conditions specified by the manufacturer.

Evidence shall be provided by the manufacturer.

4.3.2 R If copper pipes are used, they shall comply with the requirements for copper tubing for pipelines given

in ISO 7396-1.

NOTE The requirement in 4.3.2 allows the use of the same stock of copper pipes as is used for the installation of pipeline

systems for compressed medical gases and vacuum in accordance with ISO 7396-1.

Evidence shall be provided by the manufacturer.

4.3.3 R All components of the system which come in contact with anaesthetic gases and vapours shall be

cleaned in accordance with ISO 15001.

4.3.4 R If lubricants are used, they shall be compatible with anaesthetic gases and vapours at the operating

conditions.

Evidence shall be provided by the manufacturer.

4.3.5 All precautions shall be taken to maintain cleanliness during transportation, storage and installation.

5 Power device

5.1 The power device shall be used solely to power the AGS disposal system.

5.2 The power device shall be one of the following:

a) an exhaust ejector, for each type 1 terminal unit, driven by compressed air from an air compressor system and

a pipeline system complying with ISO 7396-1, provided with a means of adjusting the flow from the receiving

system through the type 1 terminal unit to meet the requirements specified in 8.1 a) or b); see Figure 2a);

b) an exhaust ejector for each type 2 terminal unit, driven by compressed air from an air compressor system and

a pipeline system complying with ISO 7396-1, provided with a means of adjusting the flow from the receiving

system to meet the requirements specified in 8.1 c); see Figure 2b);

c) one or more fans, blowers or dedicated vacuum pumps, provided with means of adjusting and controlling the

vacuum level in the pipeline system and therefore the flow through each type 1 terminal unit within the limits

specified in 8.1 a) or b), regardless of the number of terminal units in use; see Figure 2 c).

6 © ISO 2000 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 7396-2:2000(E)

Key

1 Compressed-air-driven power device 6 Ambient air

2 Vacuum pump/fan/blower power device 7 Compressed medical air

3 Flow regulating valve 8 Receiving system

4 Type 1 terminal unit 9 Discharge

5Type2terminalunit

Figure 2 — Typical examples of power devices

© ISO 2000 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 7396-2:2000(E)

6 Indicating systems

Means shall be provided to indicate to the operator that the power device is operating.

7 Pipelines, connecting assemblies and disposal hoses

7.1 If the connecting assemblies or disposal hoses are readily accessible to the operator, the connecting

assembly or the disposal hoses shall be type-specific and the dimensions of its connectors shall not comply with

ISO 5359.

NOTE Examples of assemblies and hoses readily accessible to the operator are those in a ceiling flexible pendant or a

rigid ceiling column with access panels.

7.2 If the connecting assemblies or disposal hoses are not readily accessible to the operator without significant

disassembly of fixed equipment, the connectors of the assembly need not be type-specific.

NOTE Examples of assemblies and hoses not readily accessible to the operator are those in hinged-arm booms, tracks

and pendants.

7.3 If the connecting assemblies are not normally replaced during their life, the assembly need not be type-

specific.

NOTE Examples of such assemblies are those used for isolation of vibration, building movement and relative movement of

the pipelines.

7.4 Means shall be provided to prevent backflow of waste gas to terminal units.

NOTE This may be achieved by, for example, individual piping or non-return valves.

8 Disposal system characteristics

8.1 Requirements

The characteristics of the AGS disposal system shall be as follows.

a) The flowrate through each type 1L terminal unit or, if not provided, at the interface point upstream of the power

device (see Figure 1) shall not exceed 50 l/min when the resistance to flow which is provided to simulate the

resistance of the receiving system is such as to produce a pressure drop of 1 kPa at 50 l/min, and shall not be

lower than 25 l/min when the resistance to flow is such as to produce a pressure drop of 2 kPa at 25 l/min (see

also ISO 8835-3:1997, subclause 9.3). The results shall be recorded on a form such as Form C.6/1 (see

annex C).

The test method for compliance is given in 8.2.

b) The flowrate through each type 1H terminal unit or, if not provided, at the interface point upstream of the power

�5

device (see Figure 1) shall be ( 75 ) l/min when the resistance of the receiving system is such as to produce

0

a pressure drop of 2 kPa at 75 l/min (see also ISO 8835-3:1997, subclause 9.4). The results shall be recorded

on Form C.6/1 (see annex C).

The test method for compliance is given in 8.2.

c) With a flowrate of 50 l/min through the socket of each type 2 terminal unit, if provided, the pressure drop shall

not exceed 7,5 kPa.

The test method for compliance is given in 8.2. The results shall be recorded on a form such as Form C.6/2 (see

annex C).

8 © ISO 2000 – All rights reserved

---------------------- Page: 13 ----------------------

ISO 7396-2:2000(E)

8.2 Test method for flowrate and pressure drop

8.2.1 General

8.2.1.1 All flow control valves (if fitted) shall be adjusted for the purpose of controlling the flow at each terminal

unit. Each terminal unit on the system shall be tested as follows:

a) with only the terminal unit under test in use;

b) for systems with more than one terminal unit, with all terminal units in use which are specified to operate at the

same time.

8.2.1.2 Testing shall be performed using ambient air.

8.2.1.3 The resolution of all pressure measuring devices shall be at most 10 % of the specified values to be

measured.

8.2.2 Test methods for disposal systems fitted with type 1 terminal units

8.2.2.1 Test devices

8.2.2.1.1 In order to simulate the resistance to flow of a low-flow receiving system complying with ISO 8835-3,

test devices which are fitted with type 1L probes and produce a pressure drop of 1 kPa at a flowrate of 50 l/min

(test device 1/50) and 2 kPa at a flowrate of 25 l/min (test device 2/25) shall be used. Typical test devices are

shown inFigure3.

8.2.2.1.2 In order to simulate the resistance to flow of a high-flow receiving system complying with ISO 8835-3, a

test device which is fitted with a type 1H probe and produces a pressure drop of 2 kPa at a flowrate of 75 l/min (test

device 2/75) shall be used. Typical test devices are shown in Figure 3.

8.2.2.2 Procedure

8.2.2.2.1 If the test devices are not precalibrated, the flowrate and the pressure drop of each test device shall

be checked to make sure that they are in accordance with the specified values (1 kPa at 50 l/min and 2 kPa at

25 l/min or 2 kPa at 75 l/min) when connected to a suitable source of suction.

8.2.2.2.2 The power device on the AGS disposal system to be tested shall be activated.

8.2.2.2.3 The test device fitted with type 1L probe which produces 1 kPa at 50 l/min shall be inserted into each

type 1L terminal unit in turn with all the other terminal units closed. The flowrate on the test device at each terminal

unit shall be recorded.

8.2.2.2.4 The test device fittedwithtype1L probe whichproduces2kPaat 25 l/min shallbeinserted intoeach

type 1L terminal unit in turn with all the other terminal units closed. The flowrate on the test device at each terminal

unit shall be recorded.

8.2.2.2.5 Test devices fitted with type 1L probes which produce 1 kPa at 50 l/min shall be inserted into each of

several type 1L terminal units up to the design capacity of the AGS low-flow disposal system with all the other

terminal units closed. The flowrate on each test device shall be recorded at the same time.

8.2.2.2.6 A test device fitted with type 1L probes which produce 2 kPa at 25 l/min shall be inserted into each of

several type 1L terminal units up to the design capacity of the AGS low-flow disposal system with all the other

terminal units closed. The flowrate on each test device shall be recorded at the same time.

8.2.2.2.7 The test device fitted with a type 1H probe which produces 2 kPa at 75 l/min shall be inserted into each

type 1H terminal unit in turn with all the other terminal units closed. The flowrate on the test device at each terminal

unit shall be recorded.

© ISO 2000 – All rights reserved 9

---------------------- Page: 14 ----------------------

ISO 7396-2:2000(E)

Key

1 Type 1 probe 3 Fixed orifice

2 Flowmeter 4 Pressure measuring device (for calibration only)

Figure 3 — Typical test device for AGS disposal system characteristics (with type 1 terminal units)

8.2.2.2.8 Test devices fitted with type 1H probe which produce 2 kPa at 75 l/min shall be inserted into each of

several type 1H terminal units up to the design capacity of the AGS high-flow disposal system with all other

terminal units closed. The flowrate on each test device shall be recorded at the same time. Each flowrate shall be

�5

( 75 ) l/min. The results shall be recorded on a form such as Form C.6/1 (see annex C).

0

8.2.3 Test method for disposal systems fitted with type 2 terminal units

8.2.3.1 Test devices

Test devices fitted with a type 2 probe and providing flowrates up to 50 l/min shall be used.

8.2.3.2 Procedure

8.2.3.2.1 The power device on the AGS disposal system to be tested shall be activated.

8.2.3.2.2 The test device shall be inserted into each terminal unit in turn with all the other terminal units closed.

The flowrate shall be adjusted to (50� 5) l/min. The pressure shall be recorded at the inlet to the terminal unit.

8.2.3.2.3 A test device shall be inserted into each of several terminal units up to the design capacity of the AGS

disposal system with all the other terminal units closed. Each flowrate shall be adjusted to (50� 5) l/min. The

pressure at the inlet to each terminal unit shall be recorded. The results shall be recorded on a form such as Form

C.6/2 (see annex C).

10 © ISO 2000 – All rights reserved

---------------------- Page: 15 ----------------------

ISO 7396-2:2000(E)

9 Terminal units

Terminal units shall comply with ISO 9170-2.

10 Marking

10.1 Pipelines shall be marked “AGSS” or national equivalent and shall have arrows denoting the direction of flow

adjacent to valves, if fitted, at junctions and changes of direction, before and after walls and partitions, etc. at

intervals of no more than 10 m and adjacent to terminal units.

10.2 Connecting assemblies and disposal hoses shall be marked “AGSS” or national equivalent.

10.3 Marking shall be:

a) durable;

b) with letters not less than 6 mm high for the pipelines and not less than 2,5 mm high for connecting assemblies

and disposal hoses.

10.4 If colour coding is used, it shall be red magenta or in accordance with the national standard.

NOTE An example of red magenta is 3050-R40B in accordance with SS 01 91 02.

10.5 Colour coding shall be durable.

10.6 The test for durability of marking and colour coding is given in 12.4.10.

11 Pipeline installation

11.1 Pipelines and electrical services shall be either

a) run in separate compartments; or

b) separated by more than 50 mm.

11.2 The pipelines, if metallic, shall be bonded to an earth terminal as near as possible to the point at which the

pipeline enters the building. The pipelines shall not be used for earthing the electrical equipment. The relevant

parts of national regulations for electrical installations in buildings shall apply.

11.3 Pipelines shall be protected from physical damage.

EXAMPLES Damage which might be sustained from the mov

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.