ISO 18936:2012

(Main)Imaging materials — Processed colour photographs — Methods for measuring thermal stability

Imaging materials — Processed colour photographs — Methods for measuring thermal stability

This International Standard describes test methods for determining the long-term dark storage stability of colour photographic images. It is applicable to colour photographic images made with traditional photographic materials. These images are generated with chromogenic, silver dye-bleach, dye transfer, dye-diffusion-transfer "instant" systems and similar systems. The test method specified in this International Standard also covers the dark-stability of digital colour images produced with dry- and liquid-toner electrophotography, thermal dye transfer (sometimes called "dye sublimation"), and inkjet printing systems.

Matériaux pour l'image — Photographies couleurs après traitement — Méthodes de mesure de la stabilité thermique

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18936

First edition

2012-04-15

Imaging materials — Processed colour

photographs — Methods for measuring

thermal stability

Matériaux pour l’image — Photographies couleurs après traitement —

Méthodes de mesure de la stabilité thermique

Reference number

ISO 18936:2012(E)

©

ISO 2012

---------------------- Page: 1 ----------------------

ISO 18936:2012(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 18936:2012(E)

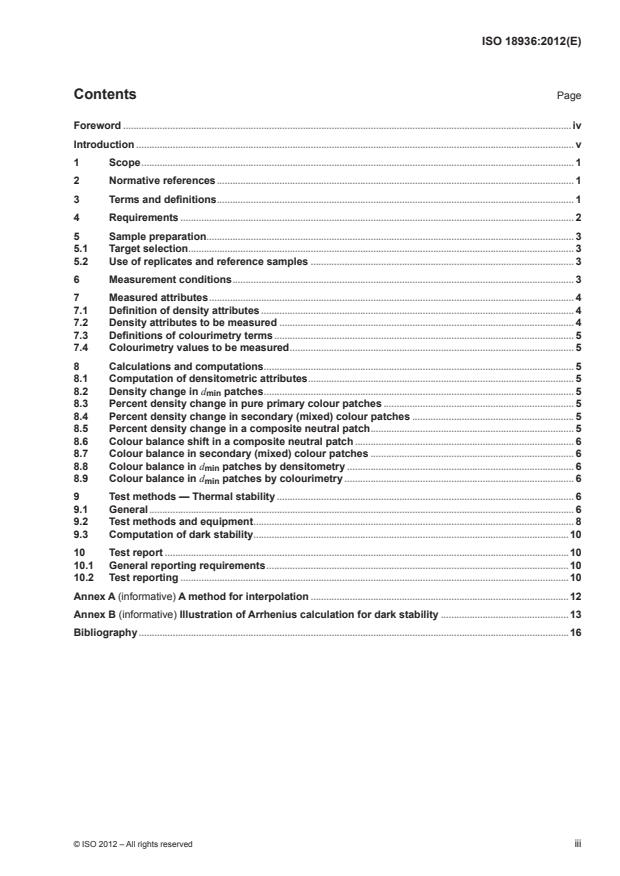

Contents Page

Foreword .iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Requirements . 2

5 Sample preparation . 3

5.1 Target selection . 3

5.2 Use of replicates and reference samples . 3

6 Measurement conditions . 3

7 Measured attributes . 4

7.1 Definition of density attributes . 4

7.2 Density attributes to be measured . 4

7.3 Definitions of colourimetry terms . 5

7.4 Colourimetry values to be measured . 5

8 Calculations and computations . 5

8.1 Computation of densitometric attributes . 5

8.2 Density change in d patches . 5

min

8.3 Percent density change in pure primary colour patches . 5

8.4 Percent density change in secondary (mixed) colour patches . 5

8.5 Percent density change in a composite neutral patch . 5

8.6 Colour balance shift in a composite neutral patch . 6

8.7 Colour balance in secondary (mixed) colour patches . 6

8.8 Colour balance in d patches by densitometry . 6

min

8.9 Colour balance in d patches by colourimetry . 6

min

9 Test methods — Thermal stability . 6

9.1 General . 6

9.2 Test methods and equipment . 8

9.3 Computation of dark stability .10

10 Test report .10

10.1 General reporting requirements .10

10.2 Test reporting .10

Annex A (informative) A method for interpolation .12

Annex B (informative) Illustration of Arrhenius calculation for dark stability .13

Bibliography .16

© ISO 2012 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 18936:2012(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International

Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 18936 was prepared by Technical Committee ISO/TC 42, Photography.

iv © ISO 2012 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 18936:2012(E)

Introduction

This International Standard covers the methods and procedures for measuring the long-term, dark storage

stability (thermal stability) of colour photographs.

Today, the majority of photographs are made with colour dyes and pigments. The length of time that such

photographs are to be kept can vary from a few days to many hundreds of years, and the importance of image

stability can be correspondingly small or great. Often the ultimate use of a particular photograph may not be

known at the outset. Knowledge of the useful life of colour photographs is important to many users, especially

since stability requirements often vary depending upon the application. For museums, archives and others

responsible for the care of colour photographic materials, an understanding of the behaviour of these materials

under various storage and display conditions is essential if they are to be preserved in good condition for long

periods of time.

Any change in density, contrast or stain, whether due to colourant fading, changes in colourant morphology or

discolouration of residual substances will change the appearance of the photograph.

The most damaging change tends to be contrast balance distortions brought about by differential fading of

the three image colourants. These manifest themselves as shifts in colour balance from highlights to shadows

that are especially noticeable in a scale of neutrals, for example a shift from magenta to green due to fading

of the photograph’s magenta image colourant, or from yellow to blue or cyan to red due to fading of the yellow

or cyan colourant.

The second most consequential change is that caused by an increase in stain. The result may simply be a

discolouration of the D areas or a change in the D colour balance.

min min

Cyan, magenta, yellow and sometimes black, red, green and blue colourants that are dispersed in transparent

binder layers, or absorbed onto special receiver layers coated onto transparent or white opaque supports, form

the images of most modern colour photographs. Colour photographic images typically fade during storage

and display; they will usually also change in colour balance because the image colourants seldom fade at the

same rate. In addition, a yellowish (or occasionally other colour) stain may form and physical degradation may

occur, such as embrittlement and cracking of the support and image layers. The rate of fading and staining

is governed principally by the intrinsic stability of the colour photographic material and by the conditions

under which the photograph is stored and displayed. The quality of chemical processing or post-processing

is another important factor. Post-processing treatments and, in the case of digitally generated photographs,

post-production treatments, such as application of lacquers, plastic laminates and retouching colours, also

may affect the stability of colour materials.

The three main factors that influence storage behaviour, or dark stability, are the temperature and relative

humidity of the air that has access to the photograph, as well as atmospheric pollutants to which the photograph

is exposed. High temperature, particularly in combination with high relative humidity, will accelerate the chemical

reactions that can lead to degradation of one or more of the image colourants. Low-temperature, low-humidity

storage, on the other hand, can greatly prolong the life of photographic colour images for typical materials.

Other potential causes of image degradation are microorganisms and insects.

Most modern photographs degrade too slowly under normal room conditions to permit evaluation of their dark

storage stability within reasonable periods. However, it is possible to assess the probable, long-term changes

of some photographs under low and moderate keeping conditions with accelerated, high-temperature tests,

because recognizable losses in image quality under high temperatures are apt to be generated also under

milder temperatures, if at a slower pace. The effects of relative humidity on thermal degradation can also be

evaluated with Arrhenius tests conducted at two or more humidity levels.

Long-term changes in image density, colour balance and stain level can be reasonably estimated only when

good correlation has been confirmed between accelerated tests and actual conditions of use.

Density changes induced by the test conditions and measured during and after incubations include those in the

support and in the various auxiliary layers that may be in a particular product. With most materials, however,

the major changes occur in the image-bearing layer. An exception to this is found in some inkjet papers where

the inks are thermally stable and substrate yellowing is the failure mode (see Reference [9]).

© ISO 2012 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 18936:2012(E)

The tests for predicting the stability of colour photographic images in dark storage are based on an adaptation of

the Arrhenius method described by Bard et al. (see References [2] and [3]) and earlier references by Arrhenius,

Steiger and others (see References [4], [5] and [6]). Although this method is derived from well understood and

proven theoretical precepts of chemistry, the validity of its application to predicting changes of photographic

images rests on empirical confirmation. Although many chromogenic-type colour products yield image fading

and staining data in both accelerated and non-accelerated dark ageing tests that are in agreement with the

Arrhenius relationship, some other types of products do not. For example, integral-type instant colour print

materials often exhibit atypical staining at elevated temperatures; treatment of some chromogenic materials at

temperatures above 80 °C and 60 %RH may cause loss of incorporated high-boiling solvents and abnormal

image degradation; and the dyes of silver dye-bleach images deaggregate at combinations of very high

temperature and high relative humidity, causing abnormal changes in colour balance and saturation (see

Reference [7] in the bibliography). In general, photographic materials tend to undergo dramatic changes at

relative humidities above 60 % (especially at the high temperatures employed in accelerated tests) owing to

changes in the physical properties of gelatine and other binder materials. Lower maximum relative humidities

may need to be tested for some of the more humidity-sensitive inkjet materials because of phase changes such

as melting point or glass transition temperature.

vi © ISO 2012 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 18936:2012(E)

Imaging materials — Processed colour photographs — Methods

for measuring thermal stability

1 Scope

This International Standard describes test methods for determining the long-term dark storage stability of

colour photographic images.

It is applicable to colour photographic images made with traditional photographic materials. These images

are generated with chromogenic, silver dye-bleach, dye transfer, dye-diffusion-transfer “instant” systems and

similar systems. The test method specified in this International Standard also covers the dark-stability of digital

colour images produced with dry- and liquid-toner electrophotography, thermal dye transfer (sometimes called

“dye sublimation”), and inkjet printing systems.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced document

(including any amendments) applies.

ISO 5-3, Photography and graphic technology — Density measurements — Part 3: Spectral conditions

ISO 5-4, Photography and graphic technology — Density measurements — Part 4: Geometric conditions for

reflection density

ISO 11664-4, Colorimetry — Part 4: CIE 1976 L*a*b* Colour space

ISO 18911, Imaging materials — Processed safety photographic films — Storage practices

ISO 18913, Imaging materials — Permanence — Vocabulary

ISO 18920, Imaging materials — Reflection prints — Storage practices

ISO 18924, Imaging materials — Test method for Arrhenius-type predictions

ISO 13655, Graphic technology — Spectral measurement and colorimetric computation for graphic arts images

ISO 18941, Imaging materials — Colour reflection prints — Test method for ozone gas fading stability

ISO 18944, Imaging materials — Reflection colour photographic prints — Test print construction and

1)

measurement

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18913 and the following apply.

3.1

operational control point

set point for equilibrium conditions measured at sensor location(s) in an exposure device

[ASTM G 113]

1) To be published.

© ISO 2012 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 18936:2012(E)

3.2

operational fluctuations

positive and negative deviations from the setting of the sensor at the operational control set point during

equilibrium conditions in a laboratory-accelerated weathering device

NOTE The operational fluctuations are the result of unavoidable machine variables and do not include measurement

uncertainty. The operational fluctuations apply only at the location of the control sensor and do not imply uniformity of

conditions throughout the test chamber.

[ASTM G 113]

3.3

operational uniformity

range around the operational control point for measured parameters within the intended exposure area within

the limits of intended operational range

[ASTM G 113]

3.4

uncertainty (of measurement)

parameter, associated with the result of a measurement, that characterizes the dispersion of the values that

could be reasonably attributed to the measurand

NOTE 1 The parameter may be, for example, a standard deviation (or a given multiple of it), or the half-width of an

interval having a stated confidence level.

NOTE 2 Uncertainty of measurement comprises, in general, many components. Some of these components may be

evaluated from statistical distribution of the results of series of measurements and can be characterized by experimental

standard deviations. The other components, which can also be characterized by standard deviations, are evaluated from

assumed probability distributions based on experience or other information.

NOTE 3 It is understood that the result of the measurement is the best estimate of the value of the measurand, and

that all components of uncertainty, including those arising from systematic effects, such as components associated with

corrections and reference standards, contribute to the dispersion.

[ASTM G 113]

4 Requirements

This International Standard specifies a set of recommended test methods with associated requirements for

permitted reporting. Data from these tests shall not be used to make life expectancy claims, such as time-

based print lifetime claims, either comparative or absolute. Conversion of data obtained from these methods

for the purpose of making public statements regarding product life shall be in accordance with the applicable

International Standard(s) for specification of print life.

The test methods in this International Standard may be useful as stand-alone test methods for comparison of

the stability of image materials with respect to one specific failure mode. Data from the test methods of this

International Standard may be used in stand-alone reporting of the absolute or comparative stability of image

materials with respect to the specific failure mode dealt with in this International Standard, when reported

in compliance with the reporting requirements of this International Standard. Caution shall be used when

comparing test results for different materials. Comparisons shall only be made when using equipment with

matching specifications, under matching test conditions.

Further clarification is required for this method because it makes use of the Arrhenius methodology which may

directly lead to a predicted product lifetime. Fundamentally, the Arrhenius method defines a rate of change

(see ISO 18924). This International Standard makes use of the Arrhenius method only as a predictor of rate of

change for chemical reactions, not as a predictor of print longevity.

2 © ISO 2012 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 18936:2012(E)

5 Sample preparation

5.1 Target selection

For general testing purposes, users of this International Standard are free to choose whatever target, patches

and starting densities they feel are appropriate for their testing needs. An example of such a target is included

in ISO 18944 along with requirements and recommendations for sample preparation. Applicable International

Standard(s) for specification of print life may require the use of specific targets. Other recommendations for

sample preparation are contained in ISO 18909.

5.2 Use of replicates and reference samples

At least two replicate prints are required. Replicates shall be located for testing in different regions of the test

chamber volume.

It is recommended that reference samples be included in every exposure test to track consistency of the test

procedures as well as unintended changes of test conditions (see Reference [21]).

6 Measurement conditions

Measurements and sample holding for measurement and next test phase preparation shall be conducted in a

controlled environment with no time constraint, or in a less controlled environment with a time constraint. The

measurement environment and sample holding environment can influence measured densities.

NOTE 1 “Sample holding environment” refers to the environment in which samples are held between test phases, such

as before and after measurement, while the samples are not in the active test environment.

The controlled sample holding environment with no time constraint shall meet the following set of conditions:

samples shall be kept in the dark at 23 °C ± 2 °C and at a relative humidity of (50 ± 10) % while waiting for

measurement and while holding between test stages.

The sample holding environment shall be ozone-free (≤2 nl/l average ozone concentration over any 24 h period)

for ozone-sensitive samples. Ozone sensitivity is determined in accordance with ISO 18941 and ISO 18944.

A material that is not sensitive to ozone shall have demonstrated no measurable D or printed patch colour

min

change at ambient ozone exposure levels and measurement condition temperature and humidity, over time

periods consistent with measurement and test staging time periods.

The controlled measurement environment with no measurement process time constraint shall meet the

following set of conditions: ambient illuminance on the sample surface no greater than 200 lx, temperature of

23 °C ± 2 °C and a relative humidity of (50 ± 10) %, and ozone-free (≤2 nl/l average ozone concentration over

any 24 h period) for ozone-sensitive samples.

When sample holding and/or measurement are conducted in a less controlled environment, samples shall

be held or measured in the less controlled environment for a maximum of 2 h for each test stage. The less

controlled environment may be unfiltered for ozone, and shall have a maximum relative humidity of 75 % and

maximum temperature of 30 °C, with ambient illuminance on the sample surface less than or equal to 1 000 lx.

NOTE 2 Stray light decreases the accuracy of measurements taken in less controlled lighting environments. Shielding

the measurement instrument from direct lighting so that the actual measurement surface lighting is no more than 200 lx

can improve measurement accuracy and repeatability.

The temperature and humidity tolerances for the sample holding and measurement environments apply

specifically to the vicinities in which the samples are held and measured. Operational fluctuations, operational

uniformity and uncertainty of measurement shall be contained within the stated tolerances in those vicinities.

The measurement environment and sample holding environment, with respect to temperature, percentage relative

humidity, ozone and light levels, and with respect to fluctuations and uniformity shall be reported in the test report.

The CIE colour coordinates of the D patch (unprinted paper) shall be measured using ISO 13655

min

measurement condition M0 for the relative spectral power distribution of the flux incident on the specimen

© ISO 2012 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 18936:2012(E)

surface. White backing is recommended in accordance with ISO 13655. Report the backing used or report the

material opacity, according to ISO 2471, such that backing has no influence on the measurement. Measurement

conditions shall be consistent throughout the test process. Conforming to ISO 13655, calculated tristimulus

values and corresponding CIELAB values shall be computed using CIE illuminant D50 and the CIE 1931

standard colorimetric observer (often referred to as the 2° standard observer).

NOTE 3 With completely opaque materials such as the aluminium substrate used in outdoor testing, the backing has

no relevance.

Optical densities shall be measured according to ISO 5-3, with the relative spectral power distribution of the

flux incident on the specimen surface conforming to CIE illuminant A, ISO 13655 measurement condition M0,

and spectral products conforming to Status A or Status T density, as appropriate for the material under test.

White backing is recommended in accordance with ISO 5. Use ISO 5 standard reflection density as defined in

ISO 5-4, allowing either annular influx mode or annular efflux mode. Either white or black backing is allowed.

Report the backing used. Measurement conditions shall be consistent throughout the test process.

NOTE 4 When testing in accordance with an image life specification standard, then either standard status A or status

T density is selected according to that specification standard.

A single measurement instrument shall be used for all of the measurements taken pertaining to a particular

test. For example, initial patch values of a test target print and subsequent degraded patch values of that

particular test target print shall be measured using the same measurement instrument. Replicate prints may

be measured on separate measurement instruments as long as each is consistently measured on the same

instrument used for its initial readings. According to best practice, in the case of equipment failure the test

should be invalidated. A replacement instrument with a known offset, determined for the test measurement

conditions and materials such as those being measured, may be used when the original instrument is not

available. In this case, all measurements shall be corrected with the known offset.

NOTE 5 It is useful to retain freezer check print samples of the measurement materials so that instrument offsets can

be measured if needed. Offset measurements from materials matched to those under test are preferred to measurements

using BCRA tiles. Refer to ISO 18920 for print storage methods.

7 Measured attributes

7.1 Definition of density attributes

The symbol for measured density is d.

7.2 Density attributes to be measured

The following Status A or Status T densities of the specimens shall be measured before and after the

treatment interval.

a) dN(R) , dN(G) , dN(B)

t t t

the red, green and blue Status A or Status T densities of neutral patches that have been treated for time t,

where t takes on values from 0 to the end of the test;

b) dC(R) , dM(G) , dY(B)

t t t

the red, green and blue Status A or Status T densities of cyan, magenta and yellow colour patches that

have been treated for time t, where t takes on values from 0 to the end of the test,

c) dR(G) , dR(B) , dG(R) , dG(B) , dB(R) , dB(G)

t t t t t t

the red, green and blue Status A or Status T densities of the composite secondary R, G, B colour patches

that have been treated for time t, where t takes on values from 0 to the end of the test.

4 © ISO 2012 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 18936:2012(E)

7.3 Definitions of colourimetry terms

L* is CIELAB lightness, a* and b* are the CIELAB a* and b* coordinates respectively, as defined in ISO 11664-4.

7.4 Colourimetry values to be measured

The following colourimetry values of the specimens, prepared as described in Clause 5, shall be measured

before and after the treatment interval.

L*t, a*t, b*t

The lightness, red-green, and blue-yellow colour coordinates for the unprinted areas of specimens (paper

white) that have been treated for time t, where t takes on values from 0 to the end of the test.

8 Calculations and computations

8.1 Computation of densitometric attributes

The calculations given in 8.2 to 8.9 shall be performed for patches with initial densities of 0,5, 1,0 and 1,5. Other

starting densities may be used in addition, depending on the service needs of the specific product being tested.

8.2 Density change in d patches

min

a) Red density change: Δd (R) = d (R) - d (R)

min t min t min 0

b) Green density change: Δ d (G) = d (G) - d (G)

min t min t min 0

c) Blue density change: Δ d (B) = d (B) - d (B)

min t min t min 0

8.3 Percent density change in pure primary colour patches

a) Cyan patch: %ΔdC(R) = [(dC(R) - dC(R) ) ÷ dC(R) ] × 100

t t 0 0

b) Magenta patch: %ΔdM(G) = [(dM(G) - dM(G) ) ÷ dM(G) ] × 100

t t 0 0

c) Yellow patch: %ΔdY(B) = [(dY(B) - dY(B) ) ÷ dY(B) ] × 100

t t 0 0

8.4 Percent density change in secondary (mixed) colour patches

a) Magenta in Red patch: %ΔdR(G) = [(dR(G) - dR(G) ) ÷ dR(G) ] × 100

t t 0 0

b) Yellow in Red patch: %ΔdR(B) = [(dR

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.