ISO/IEC 24734:2014

(Main)Information technology — Office equipment — Method for measuring digital printing productivity

Information technology — Office equipment — Method for measuring digital printing productivity

ISO/IEC 24734:2014 specifies a method for measuring the productivity of digital printing devices with various office applications and print job characteristics. It is applicable to digital printing devices, including single-function and multi-function devices, regardless of print technology (e.g. inkjet, laser). Devices can be equipped with a range of paper feed and finishing options either directly connected to the computer system or via a network. It is intended to be used for black and white (B&W) as well as colour digital printing devices. It allows for the comparison of the productivity of machines operating in various available modes (simplex, duplex, size of substrates, etc.) and office applications when the test system environment, operating modes, and job mix for each machine are held identical. ISO/IEC 24734:2014 includes test files, test setup procedure, test runtime procedure, and the reporting requirements for the digital printing productivity measurements. ISO/IEC 24734:2014 is not intended to be used for devices which are not able to print on a media size of A4/8.5"x11" or for devices, which are not able to collate multiple copies of a print. ISO/IEC 24734:2014 is not intended to replace a manufacturer's rated speeds. The productivity of a digital printing device depends on factors other than the printing device itself. These include, but are not limited to, computer manufacturer and model, central processor type and speed, RAM and hard disk memory capacity and speed, software driver, version of the application being used, operating system, and the type and speed of the communication path from computer to printing device, etc. Because of this, in order to make useful and accurate direct comparisons of printing productivity with ISO/IEC 24734:2014, the same computer system hardware and software have to be used for measuring the printing devices, if, for the purpose of being directly compared one to another. For every printing productivity measurement, the basic specifications of the computer hardware and software have to be included with the results of the printing productivity measurement.

Technologies de l'information — Équipements de bureau — Méthode de mesure de la productivité d'impression numérique

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 24734

Second edition

2014-07-01

Information technology — Office

equipment — Method for measuring

digital printing productivity

Technologies de l’information — Équipements de bureau — Méthode

de mesure de la productivité d’impression numérique

Reference number

ISO/IEC 24734:2014(E)

©

ISO/IEC 2014

---------------------- Page: 1 ----------------------

ISO/IEC 24734:2014(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO/IEC 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2014 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/IEC 24734:2014(E)

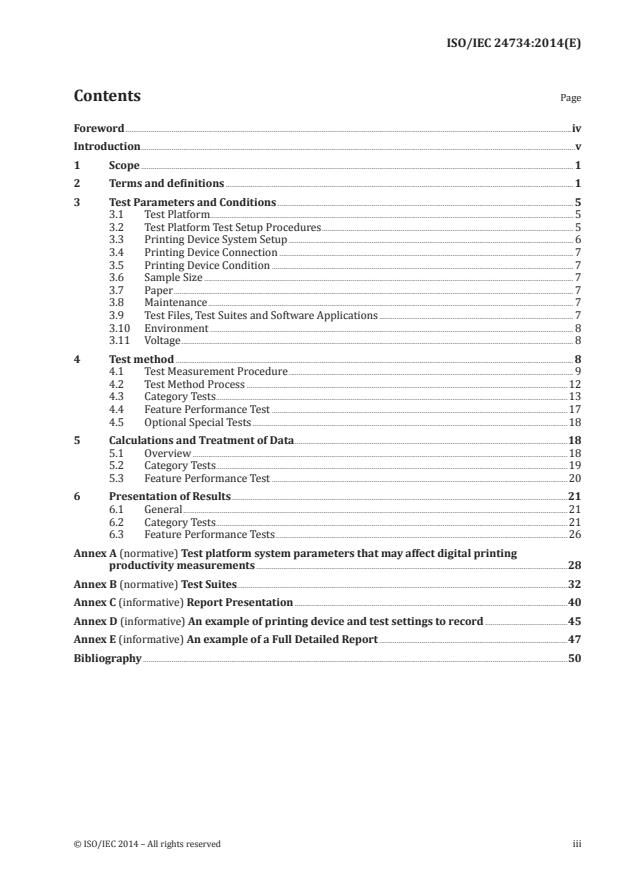

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Terms and definitions . 1

3 Test Parameters and Conditions . 5

3.1 Test Platform . 5

3.2 Test Platform Test Setup Procedures . 5

3.3 Printing Device System Setup . 6

3.4 Printing Device Connection . 7

3.5 Printing Device Condition . 7

3.6 Sample Size . 7

3.7 Paper . 7

3.8 Maintenance . 7

3.9 Test Files, Test Suites and Software Applications . 7

3.10 Environment . 8

3.11 Voltage . 8

4 Test method . 8

4.1 Test Measurement Procedure . 9

4.2 Test Method Process .12

4.3 Category Tests .13

4.4 Feature Performance Test .17

4.5 Optional Special Tests .18

5 Calculations and Treatment of Data .18

5.1 Overview .18

5.2 Category Tests .19

5.3 Feature Performance Test .20

6 Presentation of Results .21

6.1 General .21

6.2 Category Tests .21

6.3 Feature Performance Tests .26

Annex A (normative) Test platform system parameters that may affect digital printing

productivity measurements .28

Annex B (normative) Test Suites .32

Annex C (informative) Report Presentation .40

Annex D (informative) An example of printing device and test settings to record .45

Annex E (informative) An example of a Full Detailed Report .47

Bibliography

.50

© ISO/IEC 2014 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/IEC 24734:2014(E)

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are

members of ISO or IEC participate in the development of International Standards through technical

committees established by the respective organization to deal with particular fields of technical

activity. ISO and IEC technical committees collaborate in fields of mutual interest. Other international

organizations, governmental and non-governmental, in liaison with ISO and IEC, also take part in the

work. In the field of information technology, ISO and IEC have established a joint technical committee,

ISO/IEC JTC 1.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for

the different types of document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

Details of any patent rights identified during the development of the document will be in the Introduction

and/or on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/IEC JTC 1, Information technology, Subcommittee

SC 28, Office equipment.

This second edition cancels and replaces the first edition (ISO/IEC 24734:2009), of which it constitutes

a minor revision.

iv © ISO/IEC 2014 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/IEC 24734:2014(E)

Introduction

Many digital printing devices produce printed pages at a different rate than their nominal speed when

running with different modes (simplex, duplex, print quality modes), different substrate weight, system

environments, applications and file content, and finishing options. The degree to which a reduction

in productivity is experienced depends significantly on multiple parameters of the job workflow. The

most dominant of the parameters of the job workflow are: system environment, application, and job

characteristics, such as, the number of pages in a set to be printed, single-sided or double-sided output

pages, quality mode, number of print sets to be produced, substrate weight/size used, finishing options,

and job content complexities such as monochrome vs. colour, text/vector vs. raster, page scaling,

and colour conversion. The existing International Standard (ISO/IEC 10561) only addresses printing

throughput for class 1 and class 2 printers and, therefore, is not suitable for comparing colour printing

devices or high-speed page-oriented printing devices with many finishing options and connectivity

configurations.

This International Standard provides a general method for measuring the productivity when the

above-mentioned job workflow parameters for digital printing devices are taken into consideration.

This International Standard also includes a suite of test files, test-platform (hardware and software)

setup guidelines, and a procedure to be used for measuring digital printing productivity. It allows

manufacturers and buyers of digital printing devices to describe the productivity of various digital

printing devices with respect to representative office usage patterns.

© ISO/IEC 2014 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO/IEC 24734:2014(E)

Information technology — Office equipment — Method for

measuring digital printing productivity

1 Scope

This International Standard specifies a method for measuring the productivity of digital printing devices

with various office applications and print job characteristics. This International Standard is applicable

to digital printing devices, including single-function and multi-function devices, regardless of print

technology (e.g. inkjet, laser). Devices can be equipped with a range of paper feed and finishing options

either directly connected to the computer system or via a network. It is intended to be used for black and

white (B&W) as well as colour digital printing devices. It allows for the comparison of the productivity

of machines operating in various available modes (simplex, duplex, size of substrates, etc.) and office

applications when the test system environment, operating modes, and job mix for each machine are held

identical. This International Standard includes test files, test setup procedure, test runtime procedure,

and the reporting requirements for the digital printing productivity measurements.

This International Standard is not intended to be used for devices which are not able to print on a media

size of A4/8.5”x11” or for devices, which are not able to collate multiple copies of a print.

This International Standard is not intended to replace a manufacturer’s rated speeds.

The productivity of a digital printing device depends on factors other than the printing device itself. These

include, but are not limited to, computer manufacturer and model, central processor type and speed,

RAM and hard disk memory capacity and speed, software driver, version of the application being used,

operating system, and the type and speed of the communication path from computer to printing device,

etc. Because of this, in order to make useful and accurate direct comparisons of printing productivity

with this International Standard, the same computer system hardware and software have to be used for

measuring the printing devices, if, for the purpose of being directly compared one to another. For every

printing productivity measurement, the basic specifications of the computer hardware and software

have to be included with the results of the printing productivity measurement.

NOTE There are other factors that influence the number of prints that a person can make on a printing device

within a defined time period. These factors include typical job portfolio that is printed on a particular printing

device, reliability of the system, downtime due to a service call, ease-of-use, (un)loaded paper during printing,

routine maintenance, interaction with other users of the printing device and the network, etc. Such productivity

items are not taken into account within the scope or methods of this International Standard.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

category test

test pertaining to one of two separate categories: Office category and Advertising and Graphics category,

whereby the Office Category test is used to test and report FSOT, ESAT, and EFTP using content from

typical office applications and the Advertising and Graphics Category test is used to test and report

FSOT, ESAT, and EFTP using applications and files representing more complexity, higher coverage, and a

higher ratio of image and graphic content such as pictures, gradients, and embedded elements

2.2

collation

printing device’s capability to produce multiple hard copies of an electronic document in repeating

original order, such as 1234, 1234, 1234, etc, which can be achieved through either software features

that ensure proper output order or via a hardware finishing device

© ISO/IEC 2014 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/IEC 24734:2014(E)

2.3

default driver

printing device driver that is automatically selected as the default per the manufacturers’ installation

procedure

2.4

duplex printing

printing where the printing device can make a number of prints with the printing being done to both

sides of the sheet

Note 1 to entry: Other equivalent terms are “two-sided printing” or “two-sided perfecting”.

2.5

EFTP

effective throughput

average speed at which a device produces pages measured from the initiation of the job through the

complete exit of the last page of the last test set

Note 1 to entry: EFTP is expressed in images per minute (ipm). EFTP can be affected by the digital processing time

of the test set as well as the run time of the test set.

2.6

ESAT

estimated saturated throughput

rate at which a device produces pages measured from the complete exit of the last page of the first test

set through the complete exit of the last page of the last test set

Note 1 to entry: ESAT is expressed in images per minute (ipm).

2.7

feature performance percentage

ratio of the printing performance (such as FSOT and ESAT) with the subject feature ON versus the

printing device default baseline performance (without the subject feature ON)

2.8

feature performance test

optional test used to evaluate productivity changes with various printing and finishing features enabled

Note 1 to entry: The feature performance test suite is run with default printing system settings to establish a base

line, and then with the selected feature (e.g. stapling) ON, for comparison.

2.9

FSOT

first set out time

number of seconds between the initiation of the job to the complete exit of the last page of the first test

set

2.10

full detailed report

presentation of information including machine setup and measured test results

2.11

full report

presentation of results, including the FSOT, EFTP, and ESAT values for each file tested for a given category

or feature test as well as the calculated averages for the overall FSOT, EFTP, and ESAT values

2 © ISO/IEC 2014 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/IEC 24734:2014(E)

2.12

host-based controller

(printing devices with a host-based controller) page description interpreter and RIP residing in the host

computer; these processes convert the PDL into a simplified format such as a raster bitmap, and the

simplified data are then sent to the printing device

Note 1 to entry: Most of the data and images processing is done on the host computer side. The performance of the

printing device depends upon the whole system (the host computer, the data transfer, and the printing device).

2.13

initial installation state

state of the test platform after the installation and configuration of the operating system and applications

but before the installation of unique software, e.g. print driver for the printing device under test

2.14

input image equivalent

number of original electronic input images printed independent of the number of hardcopy output

sheets the images are printed on

Note 1 to entry: Input image equivalent is expressed in terms of the equivalent number of images input from the

source test file. For example, if two A4-sized input images from the test file are printed on one side of an A3 page

in simplex printing, the output printed on this A3 page is a two A4-sized input image equivalent. For another

example, if four A4-sized input images from the test file are printed in reduction on one side of an A4 page in a

4-up mode in simplex printing, the output printed on this A4 page is a four A4-sized input image equivalent.

2.15

interface

network

interface between the host and the printing device, such as a direct (via parallel, serial, USB, Firewire, or

wireless) or an indirect (via network router/server) connection

2.16

LSOT

last set out time

number of seconds between the initiation of the job to the complete exit of the last page of the last test

set

2.17

nominal printing speed

printing rate, excluding time to first page printed, and measured when producing pages in a continuous

printing mode with a single static data page using a nominal weight substrate, expressed in pages or

images per minute

2.18

PDL

page description language

specifies commands and data structures that a printing system interprets to produce an intended print

page image

2.19

PDL-based controller

[printing devices that include a PDL-based controller (such as a PostScript RIP)] host computer processing

the page information through a software application into a standardized or well-known format (with

embedded PDL and compression) and the standardized/well-known page data is sent to the printing

device via an interface/network

Note 1 to entry: The printing device’s controller has its own decompressor, PDL interpreter, and RIP, with job

storage and the required large amount of processing power. Most of the final page data processing, images

processing, and job and file management are done on the printing device side. However, the performance of the

printing device still depends upon the whole system (the host computer, the data transfer, and the printing device).

© ISO/IEC 2014 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/IEC 24734:2014(E)

2.20

printing device

produces hard copy output, or prints on media such as paper, from digital electronic documents

Note 1 to entry: The function of the device is not limited to printing only, such as is the case with multi-function

devices, which have the ability to print and perform other functions such as copy, scan, and/or digital send.

2.21

RIP

raster image processor

component used in a printing system, which produces a bitmap

2.22

set count

the total number of sets printed during a test run, with set count N, and then N (as in N test sets) × M

(number of pages in one test file) pages will be printed.

Note 1 to entry: This is often referred to as copy count in the application or print driver setting.

2.23

simplex printing

use of a printing device when only a single side of a sheet is printed on

Note 1 to entry: Single-sided printing mode is similar to the copying modes often referred to as 1:1 mode, simplex

to simplex, or single-sided originals to single-sided copies.

2.24

summary report

presentation of results including the average overall FSOT and ESAT values calculated for a given

category or feature test

2.25

test file

refers to individual files used for testing as per the test method

1)

EXAMPLE A single Microsoft Excel file within the Office test is a “test file”.

2.26

test platform

set of hardware and software system components configured to perform the collection of digital printing

productivity tests, including, but not limited to a computer installed with an operating system and

applicable application software, installed printing device software, hardware and software interfaces,

and timing devices (stopwatch or automated)

2.27

test run

refers to the operation of printing one test file, in a particular system configuration, with a particular

set and page count

Note 1 to entry: Print times are recorded for each test run.

2.28

test set

all of the pages of a single test file

1) Microsoft Excel is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by ISO and IEC of this product.

4 © ISO/IEC 2014 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/IEC 24734:2014(E)

2.29

test suite

refers to the combination of test files for each category test

EXAMPLE 1 The Office Category test suite consists of three test files.

EXAMPLE 2 The Advertising and Graphics Category test suite consists of four test files.

3 Test Parameters and Conditions

3.1 Test Platform

Due to the rapid change of computer technology, a common test platform (hardware and software)

that can be used for productivity testing over time is considered to be not practical. Instead, when a

test platform is used, the test platform system parameters that may affect digital printing productivity

measurements (see Annex A) shall be recorded.

3.2 Test Platform Test Setup Procedures

3.2.1 Initial Platform Setup

The test platform hardware should be installed as per the manufacturer’s instructions. The test platform

hardware information shall be recorded as listed in Annex A. The test platform operating system and

applications should be installed as per the manufacturer’s instructions. The test platform operating

system and application information shall be recorded as per Annex A. All settings or selections made

during installation that differ from the application’s default settings or operating system’s default

settings shall be recorded.

— The test platform should be configured for the appropriate connection environment, such as direct

USB connection or network Ethernet connection, and the information shall be recorded as per

Annex A along with all settings and selections that differ from the installation default configuration.

— It should be verified that the test platform is configured for optimal performance by evaluating

system parameters such as hard disk fragmentation and compression, swap memory size, etc. Any

settings, changes or optimizations made that differ from the installation default condition shall be

recorded.

— The test platform is now in the Initial Installation State. All recorded settings shall be included in

the Full Detailed Report.

3.2.2 Creation of Disk Image of Test Platform (optional)

Disk imaging software may be used to enable the system to be restored to the Initial Installation State.

Create the disk image after the test platform has been configured and before the print driver for the

printing device is installed. Record the disk imaging software used and all settings that differ from the

imaging software’s installation default condition.

3.2.3 Initial Test State

The test platform shall be restored to the Initial Installation State before beginning the sequence of tests

for each new printing device. Products that are of the same distinct print system can share testing and

reports. Two or more products or bundles may be part of a distinct print system when they use the same

print mechanism and operating points, and there are no differences that might be expected to affect

performance. Devices with differences that could affect performance are not part of the same distinct

print system, and are different print systems, even if they use the same print mechanism, and shall not

share testing and reports. Record the method used to establish the Initial Installation State.

© ISO/IEC 2014 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/IEC 24734:2014(E)

3.3 Printing Device System Setup

Place the printing device on a horizontal surface and setup the printing device according to the

manufacturer’s recommendation. Install the software (driver, port, etc.) recommended by the

manufacturer. Use the most recent print driver available from the manufacturer. The driver and driver

version shall be recorded on the test report.

The standard test shall be conducted using the manufacturer’s default driver for the given printing

device. If a default driver is not installed/selected automatically by the manufacturer’s installation

procedure, consult the manufacturer’s documentation and use the recommended driver. All image, print

quality, mode and speed modifiers shall be at their factory pre-set configuration for the printing device

and default installed condition for the driver. If the printing device and driver differ, then the driver

defaults shall be used. Disabling manufacturer default installed features, routines or applications, is not

allowed. Examples include, but are not limited to the following: automatic cleaning or calibration cycles,

bi-directional communications and energy save settings.

Testing shall be carried out in the specified modes, regardless of whether they are default settings or

not. For example, if the default driver setting is duplex, the setting shall be changed to simplex for the

simplex tests. Other modes that may need to be modified for specific tests include B&W mode on colour

devices, paper size, paper scaling, and collation. It is allowable to disable automatic media detect and

select plain paper. All changes to the default settings shall be recorded in the Full Detailed Report.

The file shall be rendered on the page in a size corresponding to the dimensions in the test page description.

For example, when testing an A4 sized document, the media settings shall be set to A4, and when testing

a 8.5”x11” size document, set to 8.5”x11”, and so forth. Verify the printing device and print driver default

page margin settings are not larger than 12,7 mm (0,5 inches). Adjust the settings as necessary to insure

the test page printable area is rendered correctly. Adjust the settings as necessary to insure the test

pages printable area is rendered to cover the paper page area as shown in the softcopy display of the test

file. Any modifications to the printing device or print driver settings shall be recorded. Page placement

modifiers such as page centering and auto-rotation can be used to place the image p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.