ASTM B8-23

(Specification)Standard Specification for Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

Standard Specification for Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

ABSTRACT

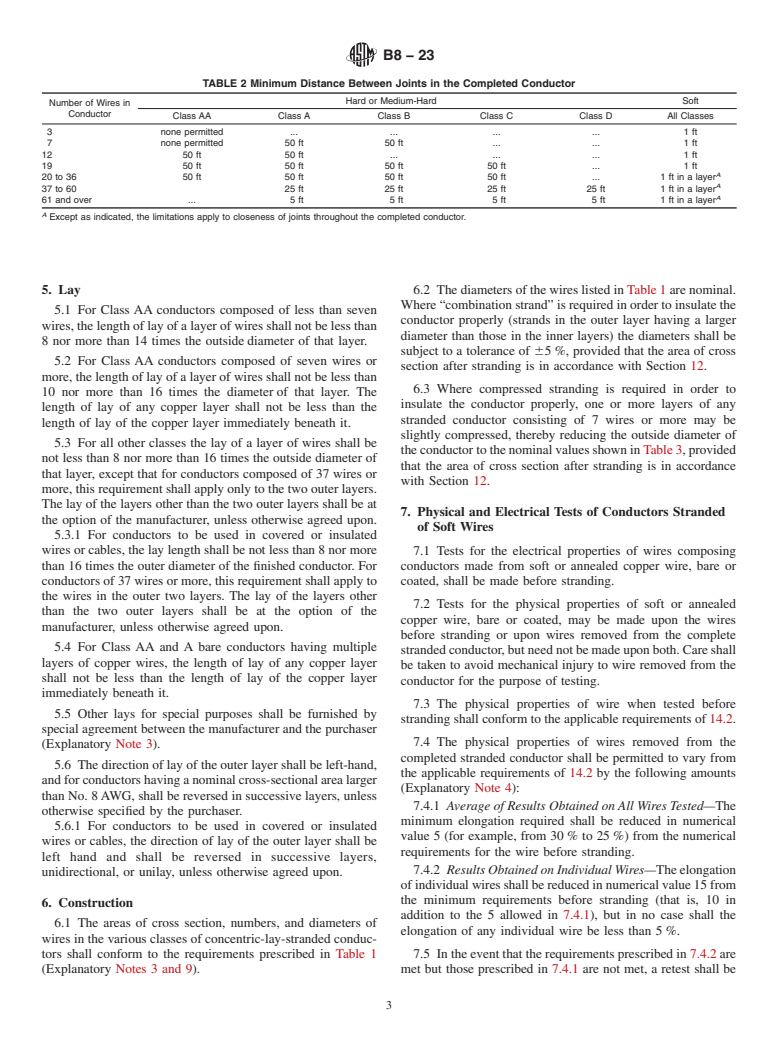

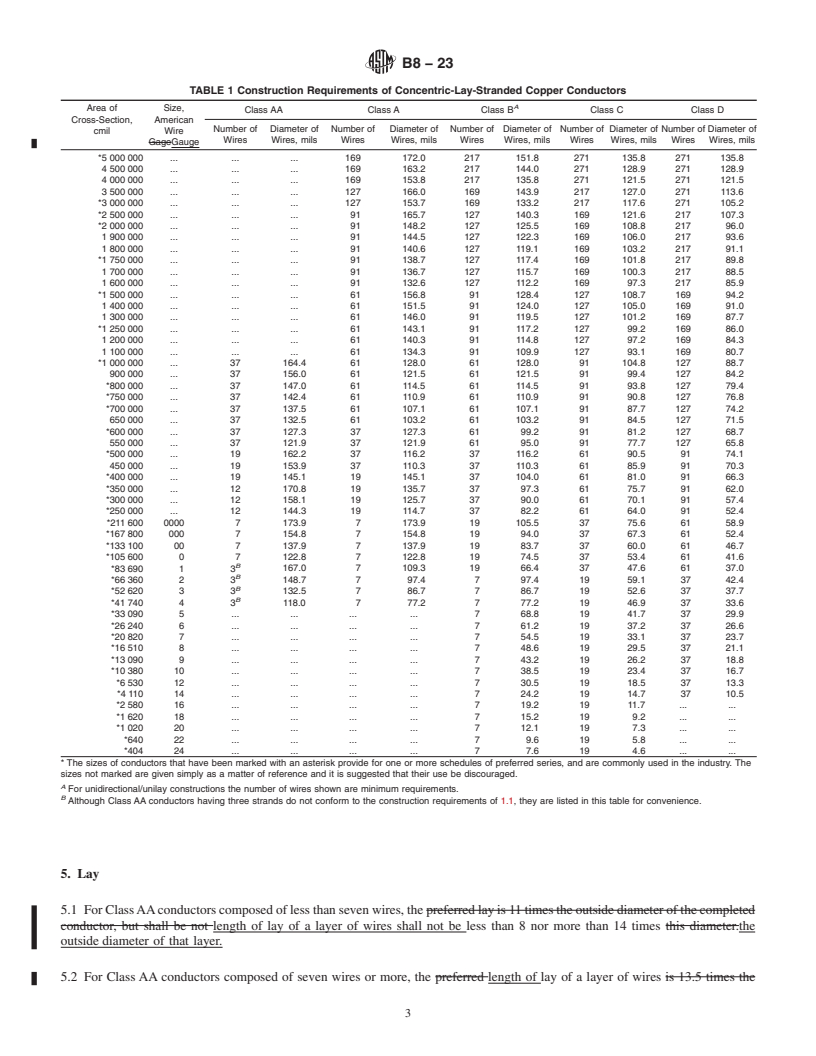

This specification covers standard requirements for bare-concentric-lay stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use for electrical purposes. These conductors shall be constructed with a central core surrounded by one or more layers of helically laid wires. The conductors shall be classified as follows: Class AA, Class A, Class B, Class C, and Class D. Sizes, number of wires, and diameter of wires in the various classes of concentric-lay-stranded conductors shall conform to the prescribed requirements. Welds and brazes may be made in rods or in wires prior to final drawing. The completed conductor of varying classes shall conform to the minimum distance required between the joints. Diameters, areas, and mass of concentric-lay-stranded copper conductors shall conform to the prescribed requirements. Physical and electrical tests of conductors stranded of hard-drawn or medium-hard-drawn wires shall be conducted before but not after stranding. The approximate mass and electrical resistance may be determined using the required increments. The material shall also conform to the temperature corrections factor for conductor resistance.

SCOPE

1.1 This specification covers bare concentric-lay-stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use for electrical purposes. These conductors shall be constructed with a central core surrounded by one or more layers of helically laid wires.

Note 1: This specification also permits conductors for use as covered or insulated electrical conductors.

Note 2: Sealed conductors, that are intended to prevent longitudinal water propagation and are further covered/insulated, are also permitted within the guidelines of this specification.

1.2 For the purposes of this specification, conductors are classified as follows (Explanatory Note 1 and Note 2):

1.2.1 Class AA—For bare conductors usually used in overhead lines.

1.2.2 Class A—For conductors to be covered with weather-resistant (weather-proof), slow-burning materials, and for bare conductors where greater flexibility than is afforded by Class AA is required.

1.2.3 Class B—For conductors to be insulated with various materials such as rubber, paper, varnished cloth, and so forth, and for the conductors indicated under Class A where greater flexibility is required.

1.2.4 Class C and Class D—For conductors where greater flexibility is required than is provided by Class B conductors.

1.3 The SI values for density are regarded as the standard. For all other properties, the inch-pound values are to be regarded as standard and the SI units may be approximate.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B8 − 23

Standard Specification for

Concentric-Lay-Stranded Copper Conductors, Hard,

1

Medium-Hard, or Soft

This standard is issued under the fixed designation B8; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 This specification covers bare concentric-lay-stranded 2.1 ASTM Standards:

conductors made from round copper wires, either uncoated or B1 Specification for Hard-Drawn Copper Wire

coated with tin, lead, or lead alloy for general use for electrical B2 Specification for Medium-Hard-Drawn Copper Wire

purposes. These conductors shall be constructed with a central B3 Specification for Soft or Annealed Copper Wire

core surrounded by one or more layers of helically laid wires. B33 Specification for Tin-Coated Soft or Annealed Copper

Wire for Electrical Purposes

NOTE 1—This specification also permits conductors for use as covered

B172 Specification for Rope-Lay-Stranded Copper Conduc-

or insulated electrical conductors.

tors Having Bunch-Stranded Members, for Electrical Con-

NOTE 2—Sealed conductors, that are intended to prevent longitudinal

water propagation and are further covered/insulated, are also permitted

ductors

within the guidelines of this specification.

B173 Specification for Rope-Lay-Stranded Copper Conduc-

1.2 For the purposes of this specification, conductors are tors Having Concentric-Stranded Members, for Electrical

classified as follows (Explanatory Note 1 and Note 2): Conductors

1.2.1 Class AA—For bare conductors usually used in over- B174 Specification for Bunch-Stranded Copper Conductors

head lines. for Electrical Conductors

1.2.2 Class A—For conductors to be covered with weather- B189 Specification for Lead-Coated and Lead-Alloy-Coated

resistant (weather-proof), slow-burning materials, and for bare Soft Copper Wire for Electrical Purposes

conductors where greater flexibility than is afforded by Class B193 Test Method for Resistivity of Electrical Conductor

AA is required. Materials

1.2.3 Class B—For conductors to be insulated with various B246 Specification for Tinned Hard-Drawn and Medium-

materials such as rubber, paper, varnished cloth, and so forth, Hard-Drawn Copper Wire for Electrical Purposes

and for the conductors indicated under Class A where greater B263 Test Method for Determination of Cross-Sectional

flexibility is required. Area of Stranded Conductors

1.2.4 Class C and Class D—For conductors where greater B354 Terminology Relating to Uninsulated Metallic Electri-

flexibility is required than is provided by Class B conductors. cal Conductors

B787/B787M Specification for 19 Wire Combination

1.3 The SI values for density are regarded as the standard.

Unilay-Stranded Copper Conductors for Subsequent Insu-

For all other properties, the inch-pound values are to be

lation

regarded as standard and the SI units may be approximate.

E29 Practice for Using Significant Digits in Test Data to

1.4 This international standard was developed in accor-

Determine Conformance with Specifications

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3. Ordering Information

Development of International Standards, Guides and Recom-

3.1 Orders for material under this specification shall include

mendations issued by the World Trade Organization Technical

the following information:

Barriers to Trade (TBT) Committee.

3.1.1 Quantity of each size and class,

3.1.2 Conductor size: circular-mil area or AWG (Section 6),

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

2

Conductors of Copper and Copper Alloys. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1915. Last previous edition approved in 2017 as B8 – 11 (2017). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0008-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B8 − 23

3.1.3 Class (see 1.2 and Table 1), 3.1.11 Place of inspection (see

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B8 − 11 (Reapproved 2017) B8 − 23

Standard Specification for

Concentric-Lay-Stranded Copper Conductors, Hard,

1

Medium-Hard, or Soft

This standard is issued under the fixed designation B8; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers bare concentric-lay-stranded conductors made from round copper wires, either uncoated or coated

with tin, lead, or lead alloy for general use for electrical purposes. These conductors shall be constructed with a central core

surrounded by one or more layers of helically laid wires.

NOTE 1—This specification also permits conductors for use as covered or insulated electrical conductors.

NOTE 2—Sealed conductors, that are intended to prevent longitudinal water propagation and are further covered/insulated, are also permitted within the

guidelines of this specification.

1.2 For the purposes of this specification, conductors are classified as follows (Explanatory Note 1 and Note 2):

1.2.1 Class AA—For bare conductors usually used in overhead lines.

1.2.2 Class A—For conductors to be covered with weather-resistant (weather-proof), slow-burning materials, and for bare

conductors where greater flexibility than is afforded by Class AA is required.

1.2.3 Class B—For conductors to be insulated with various materials such as rubber, paper, varnished cloth, and so forth, and for

the conductors indicated under Class A where greater flexibility is required.

1.2.4 Class C and Class D—For conductors where greater flexibility is required than is provided by Class B conductors.

1.3 The SI values for density are regarded as the standard. For all other properties, the inch-pound values are to be regarded as

standard and the SI units may be approximate.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved April 1, 2017Nov. 1, 2023. Published April 2017November 2023. Originally approved in 1915. Last previous edition approved in 20112017 as

B8 – 11.B8 – 11 (2017). DOI: 10.1520/B0008-11R17.10.1520/B0008-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B8 − 23

2. Referenced Documents

2

2.1 ASTM Standards:

B1 Specification for Hard-Drawn Copper Wire

B2 Specification for Medium-Hard-Drawn Copper Wire

B3 Specification for Soft or Annealed Copper Wire

B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

B172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

B173 Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conduc-

tors

B174 Specification for Bunch-Stranded Copper Conductors for Electrical Conductors

B189 Specification for Lead-Coated and Lead-Alloy-Coated Soft Copper Wire for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B246 Specification for Tinned Hard-Drawn and Medium-Hard-Drawn Copper Wire for Electrical Purposes

B263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

B354 Terminology Relating to Uninsulated Metallic Electrical Conductors

B787/B787M Specification for 19 Wire Combination Unilay-Stranded Copper Conductors for Subsequent Insulation

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size and class,

3.1.2 Conductor size: circular-mil area or AWG (Section 6),

3.1.3 Class (see 1.2 and Table 1),

3.1.4 Temper (see 13.214.2),

3.1.5 Whether coated or uncoated; if coated, designate type of c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.