ASTM E894-23

(Test Method)Standard Test Method for Anchorage of Permanent Metal Railing Systems and Rails for Buildings

Standard Test Method for Anchorage of Permanent Metal Railing Systems and Rails for Buildings

SIGNIFICANCE AND USE

4.1 This test method is intended to provide data from which applicable design data can be derived for a given anchorage.

SCOPE

1.1 This test method covers procedures to be followed in testing the performance of the anchorage of all types of new and existing permanent metal railing systems (guard, stair, and ramp-rail systems), and rails (hand, grab, and transfer rails) installed in and for agricultural, assembly, commercial, educational, industrial, institutional, recreational, and residential buildings.

1.2 This test method is applicable to railing systems and rails having major structural components made of metal and secondary components made of metal or other materials such as wood, plastics, and glass.

1.3 The test method described can be used to determine whether the anchorage of permanent metal railing systems and rails complies with anticipated performance requirements.

1.4 Specifically, this test method covers procedures for determining the static tension, shear, and moment resistance of anchorages for permanent metal railing systems, and rails in structural elements made of concrete, masonry, wood, and metal as well as related products.

1.5 No consideration is given in this test method to any possible deterioration of anchorage systems, resulting from adverse environmental conditions. The performance of special tests covering this aspect may be desirable.

1.6 Should computations make it possible to provide the needed information, testing may be employed for purposes of verification.

1.7 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 6.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E894 − 23

Standard Test Method for

Anchorage of Permanent Metal Railing Systems and Rails

1

for Buildings

This standard is issued under the fixed designation E894; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This test method covers procedures to be followed in

mine the applicability of regulatory limitations prior to use.

testing the performance of the anchorage of all types of new

For specific hazard statements, see Section 6.

and existing permanent metal railing systems (guard, stair, and

1.9 This international standard was developed in accor-

ramp-rail systems), and rails (hand, grab, and transfer rails)

dance with internationally recognized principles on standard-

installed in and for agricultural, assembly, commercial,

ization established in the Decision on Principles for the

educational, industrial, institutional, recreational, and residen-

Development of International Standards, Guides and Recom-

tial buildings.

mendations issued by the World Trade Organization Technical

1.2 This test method is applicable to railing systems and

Barriers to Trade (TBT) Committee.

rails having major structural components made of metal and

secondary components made of metal or other materials such

2. Referenced Documents

as wood, plastics, and glass.

2

2.1 ASTM Standards:

1.3 The test method described can be used to determine E4 Practices for Force Calibration and Verification of Test-

whether the anchorage of permanent metal railing systems and

ing Machines

rails complies with anticipated performance requirements. E488/E488M Test Methods for Strength of Anchors in

Concrete Elements

1.4 Specifically, this test method covers procedures for

E575 Practice for Reporting Data from Structural Tests of

determining the static tension, shear, and moment resistance of

Building Constructions, Elements, Connections, and As-

anchorages for permanent metal railing systems, and rails in

semblies

structural elements made of concrete, masonry, wood, and

E631 Terminology of Building Constructions

metal as well as related products.

E985 Specification for Permanent Metal Railing Systems

1.5 No consideration is given in this test method to any

3

and Rails for Buildings (Withdrawn 2015)

possible deterioration of anchorage systems, resulting from

adverse environmental conditions. The performance of special

3. Terminology

tests covering this aspect may be desirable.

3.1 Definitions—For definitions of terms used in this test

1.6 Should computations make it possible to provide the

method, see Terminology E631 and Specification E985.

needed information, testing may be employed for purposes of

4. Significance and Use

verification.

4.1 This test method is intended to provide data from which

1.7 The values stated in SI units are to be regarded as

applicable design data can be derived for a given anchorage.

standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for informa-

5. Apparatus

tion only and are not considered standard.

5.1 Testing Machine—Any testing machine or loading sys-

1.8 This standard does not purport to address all of the

tem capable of imposing forces accurate to within 61 %, when

safety concerns, if any, associated with its use. It is the

calibrated in accordance with Practice E4, is suitable and may

1 2

This test method is under the jurisdiction of ASTM Committee E06 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Performance of Buildings and is the direct responsibility of Subcommittee E06.56 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

on Performance of Railing Systems and Glass for Floors and Stairs. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2023. Published July 2023. Originally approved the ASTM website.

3

in 1982. Last previous edition approved in 2018 as E894 – 18. DOI: 10.1520/ The last approved version of this historical standard is referenced on

E0894-23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E894 − 23

be used, provided the requirements of specified rate of loading

and recovery are met. T

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E894 − 18 E894 − 23

Standard Test Method for

Anchorage of Permanent Metal Railing Systems and Rails

1

for Buildings

This standard is issued under the fixed designation E894; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describescovers procedures to be followed in testing the performance of the anchorage of all types of new

and existing permanent metal railing systems (guard, stair, and ramp-rail systems), and rails (hand, grab, and transfer rails) installed

in and for agricultural, assembly, commercial, educational, industrial, institutional, recreational, and residential buildings.

1.2 This test method is applicable to railing systems and rails having major structural components made of metal and secondary

components made of metal or other materials such as wood, plastics, and glass.

1.3 The test method described can be used to determine whether the anchorage of permanent metal railing systems and rails

complies with anticipated performance requirements.

1.4 Specifically, this test method covers procedures for determining the static tension, shear, and moment resistance of anchorages

for permanent metal railing systems, and rails in structural elements made of concrete, masonry, wood, and metal as well as related

products.

1.5 No consideration is given in this test method to any possible deterioration of anchorage systems, resulting from adverse

environmental conditions. The performance of special tests covering this aspect may be desirable.

1.6 Should computations make it possible to provide the needed information, testing may be employed for purposes of verification.

1.7 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to

inch-pound units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific hazard statements, see Section 6.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.56 on Performance

of Railing Systems and Glass for Floors and Stairs.

Current edition approved April 1, 2018July 1, 2023. Published May 2018July 2023. Originally approved in 1982. Last previous edition approved in 20102018 as E894 – 88

(2010).E894 – 18. DOI: 10.1520/E0894-18.10.1520/E0894-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E894 − 23

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Calibration and Verification of Testing Machines

E488/E488M Test Methods for Strength of Anchors in Concrete Elements

E575 Practice for Reporting Data from Structural Tests of Building Constructions, Elements, Connections, and Assemblies

E631 Terminology of Building Constructions

3

E985 Specification for Permanent Metal Railing Systems and Rails for Buildings (Withdrawn 2015)

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, see Terminology E631 and Specification E985.

4. Significance and Use

4.1 This test method is intended to provide data from which applicable design data can be derived for a given anchorage.

5. Apparatus

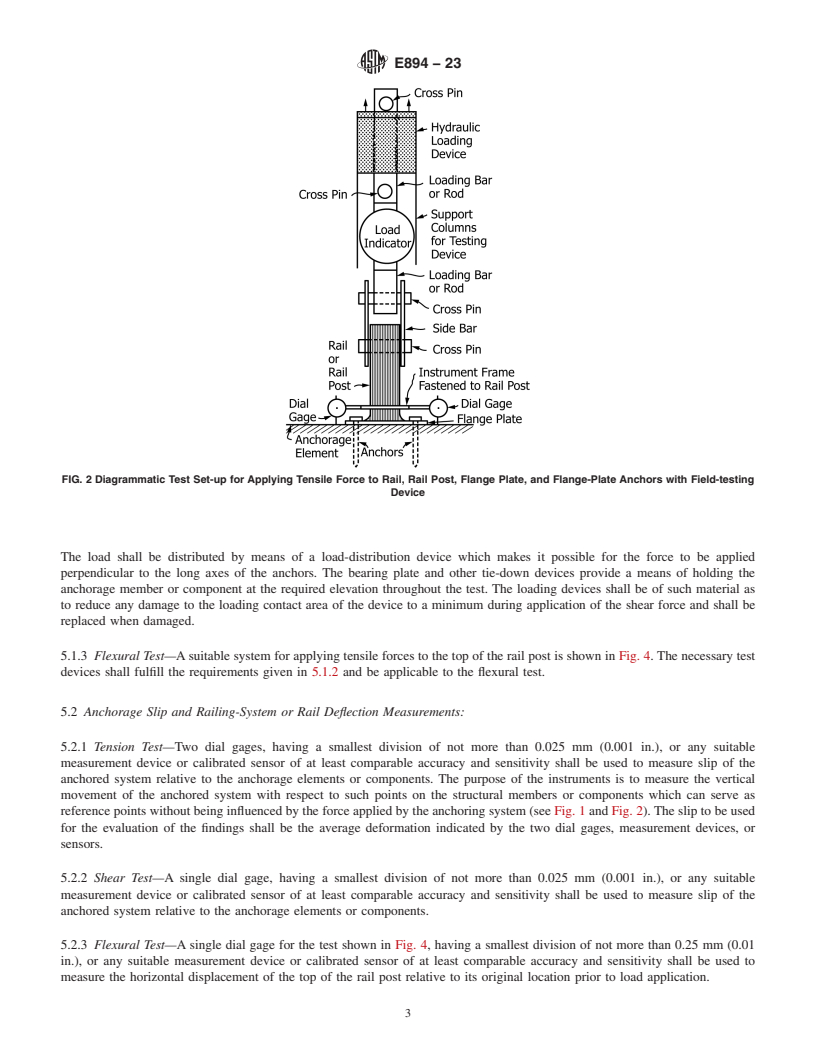

5.1 Testing Machine—Any testing machine or loading system capable of imposing forces accurate to within 61 %, when

calibrated in accordance with Practice E4, is suitable and may be used, provided the requirements of specified rate of loading and

recovery are met. The testing device shall be of sufficient capacity to prevent yielding of its various components and shall ensure

that the applied tension load remains par

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.