ASTM F3279-24

(Test Method)Standard Test Method for Ballistic-Resistant Security Glazing Materials

Standard Test Method for Ballistic-Resistant Security Glazing Materials

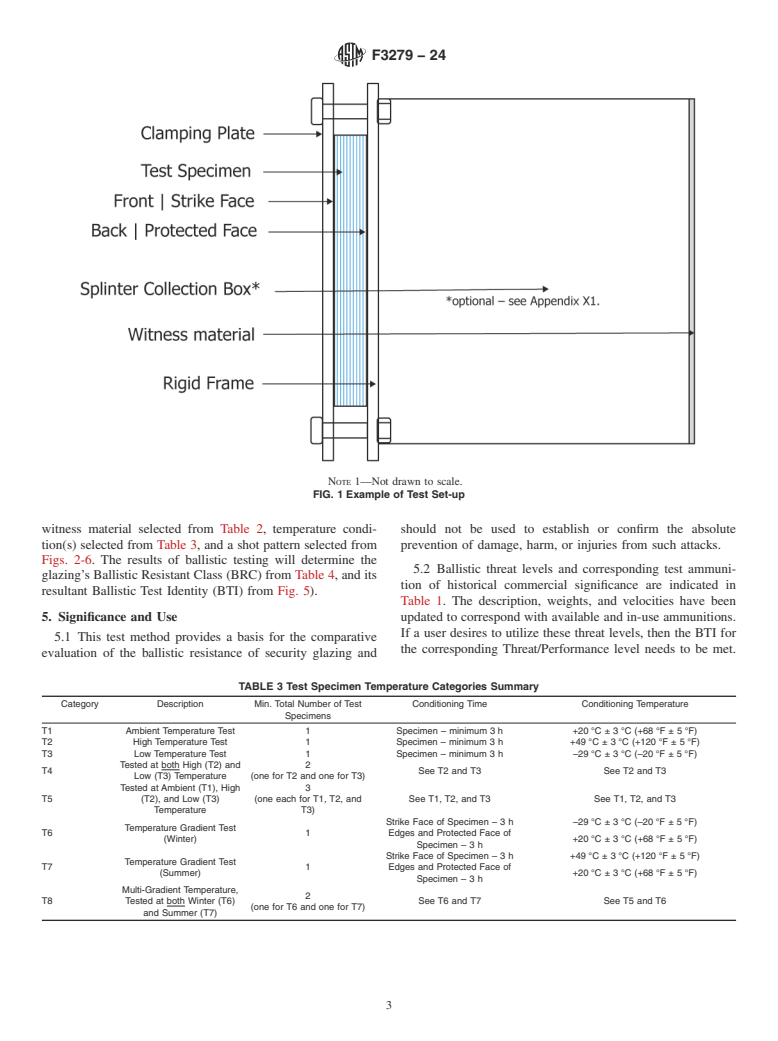

SIGNIFICANCE AND USE

5.1 This test method provides a basis for the comparative evaluation of the ballistic resistance of security glazing and should not be used to establish or confirm the absolute prevention of damage, harm, or injuries from such attacks.

5.2 Ballistic threat levels and corresponding test ammunition of historical commercial significance are indicated in Table 1. The description, weights, and velocities have been updated to correspond with available and in-use ammunitions. If a user desires to utilize these threat levels, then the BTI for the corresponding Threat/Performance level needs to be met. Additional threat level(s) and corresponding test ammunition are included in Table X1.1.

SCOPE

1.1 This test method sets forth procedures whose purpose is limited to the evaluation of the resistance of security glazing materials against ballistic threats.

1.1.1 Glazing tested in accordance with these methods is able to be assigned a ballistic resistant class (BRC) criterion.

1.1.2 Glazing tested in accordance with these methods is able to be assigned a ballistic test identity (BTI).

1.1.3 BRC’s by themselves are not indicators of performance ranking. Only the BTI is the performance indicator of ballistic resistance derived from this test method. BRC by itself is not an indication of the complete ballistic resistance performance.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3279 − 24

Standard Test Method for

1

Ballistic-Resistant Security Glazing Materials

This standard is issued under the fixed designation F3279; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Small Arms and Fragmentation Testing of Ballistic-

resistant Items

1.1 This test method sets forth procedures whose purpose is

limited to the evaluation of the resistance of security glazing 2.2 Other Documents:

materials against ballistic threats. Sporting Arms and Ammunition Manufacturer’s Institute

3

1.1.1 Glazing tested in accordance with these methods is (SAAMI)—Ammunition

able to be assigned a ballistic resistant class (BRC) criterion. United States Military Ammunition Specifications—

4

1.1.2 Glazing tested in accordance with these methods is Ammunition

able to be assigned a ballistic test identity (BTI). American Iron and Steel Institute M-1020—Structural

5

1.1.3 BRC’s by themselves are not indicators of perfor- Steel

mance ranking. Only the BTI is the performance indicator of

ballistic resistance derived from this test method. BRC by itself 3. Terminology

is not an indication of the complete ballistic resistance perfor-

3.1 Definitions:

mance.

3.1.1 bullet yaw, n—the angular deviation between the

1.2 The values stated in SI units are to be regarded as

projectile’s axis of symmetry and its line of travel.

standard. The values given in parentheses after SI units are

3.1.2 spall, n—material fragments from the back face (side

provided for information only and are not considered standard.

opposite the attack) of the test specimen that have completely

1.3 This standard does not purport to address all of the

detached from the larger test specimen body during testing.

safety concerns, if any, associated with its use. It is the

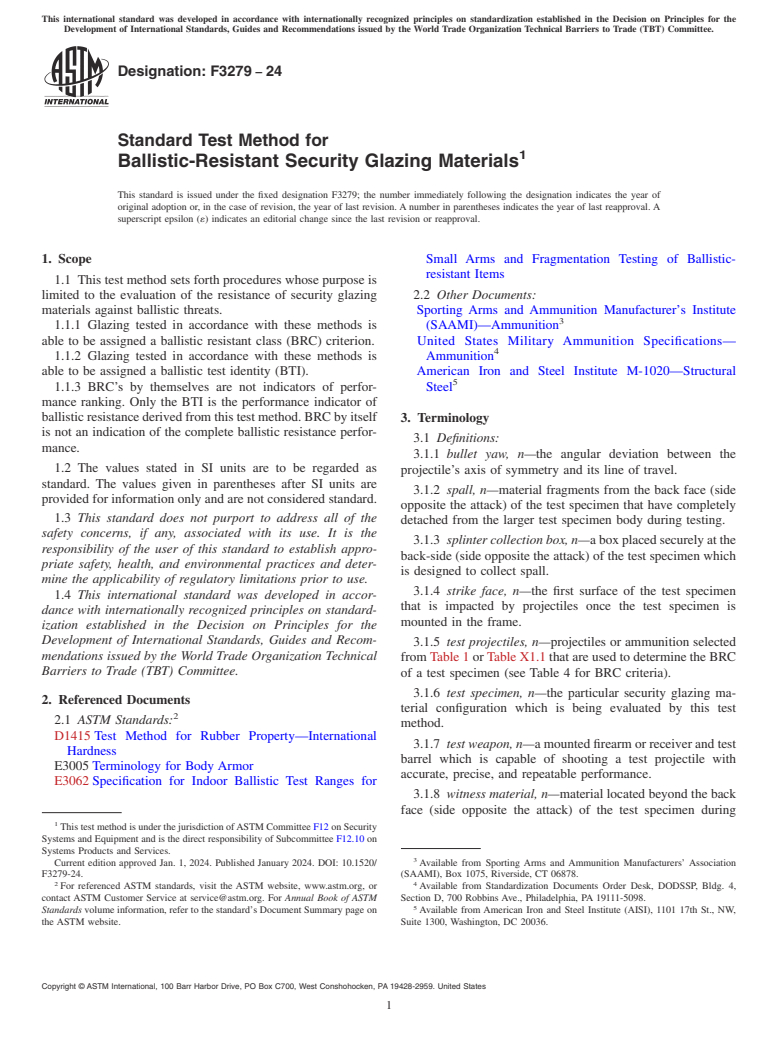

3.1.3 splinter collection box, n—a box placed securely at the

responsibility of the user of this standard to establish appro-

back-side (side opposite the attack) of the test specimen which

priate safety, health, and environmental practices and deter-

is designed to collect spall.

mine the applicability of regulatory limitations prior to use.

3.1.4 strike face, n—the first surface of the test specimen

1.4 This international standard was developed in accor-

that is impacted by projectiles once the test specimen is

dance with internationally recognized principles on standard-

mounted in the frame.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.5 test projectiles, n—projectiles or ammunition selected

mendations issued by the World Trade Organization Technical

from Table 1 or Table X1.1 that are used to determine the BRC

Barriers to Trade (TBT) Committee.

of a test specimen (see Table 4 for BRC criteria).

3.1.6 test specimen, n—the particular security glazing ma-

2. Referenced Documents

terial configuration which is being evaluated by this test

2

2.1 ASTM Standards:

method.

D1415 Test Method for Rubber Property—International

3.1.7 test weapon, n—a mounted firearm or receiver and test

Hardness

barrel which is capable of shooting a test projectile with

E3005 Terminology for Body Armor

accurate, precise, and repeatable performance.

E3062 Specification for Indoor Ballistic Test Ranges for

3.1.8 witness material, n—material located beyond the back

face (side opposite the attack) of the test specimen during

1

This test method is under the jurisdiction of ASTM Committee F12 on Security

Systems and Equipment and is the direct responsibility of Subcommittee F12.10 on

Systems Products and Services.

3

Current edition approved Jan. 1, 2024. Published January 2024. DOI: 10.1520/ Available from Sporting Arms and Ammunition Manufacturers’ Association

F3279-24. (SAAMI), Box 1075, Riverside, CT 06878.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

5

Standards volume information, refer to the standard’s Document Summary page on Available from American Iron and Steel Institute (AISI), 1101 17th St., NW,

the ASTM website. Suite 1300, Washington, DC 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3279 − 24

TAB

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.