ISO/DIS 18137-1

(Main)Leaf springs

Leaf springs

Ressorts à lames

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 18137-1

ISO/TC 227 Secretariat: JISC

Voting begins on: Voting terminates on:

2014-03-27 2014-06-27

Leaf springs —

Part 1:

Technical requirements and test methods

Ressorts à lames —

Partie 1: Exigences techniques et méthodes d’essai

ICS: 21.160

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 18137-1:2014(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2014

---------------------- Page: 1 ----------------------

ISO/DIS 18137-1:2014(E)

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as

permitted under the applicable laws of the user’s country, neither this ISO draft nor any extract

from it may be reproduced, stored in a retrieval system or transmitted in any form or by any means,

electronic, photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s

member body in the country of the requester.ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2014 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 18137-1

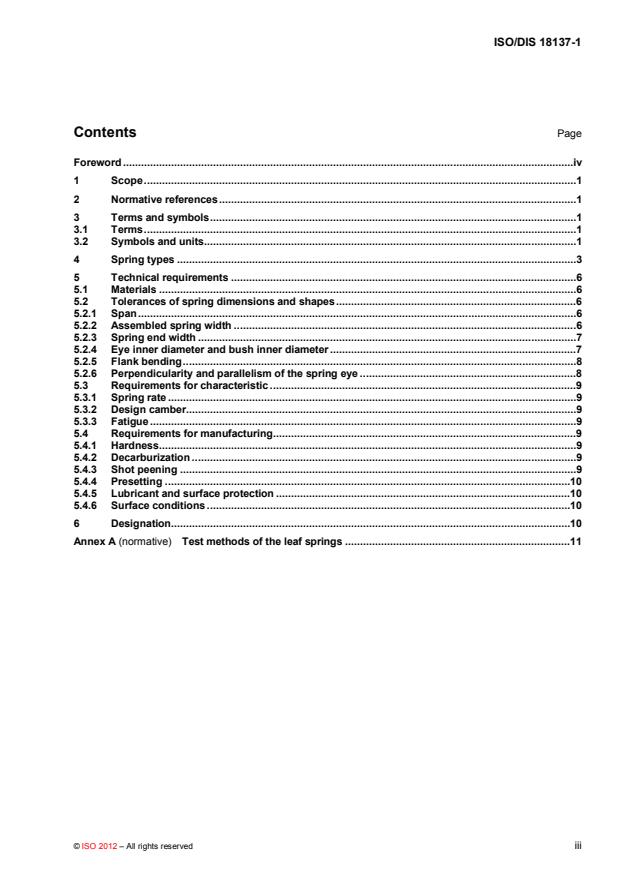

Contents Page

Foreword ......................................................................................................................................................iv

1 Scope ................................................................................................................................................1

2 Normative references .......................................................................................................................1

3 Terms and symbols ..........................................................................................................................1

3.1 Terms ................................................................................................................................................1

3.2 Symbols and units ............................................................................................................................1

4 Spring types .....................................................................................................................................3

5 Technical requirements ...................................................................................................................6

5.1 Materials ...........................................................................................................................................6

5.2 Tolerances of spring dimensions and shapes ................................................................................6

5.2.1 Span ..................................................................................................................................................6

5.2.2 Assembled spring width ..................................................................................................................6

5.2.3 Spring end width ..............................................................................................................................7

5.2.4 Eye inner diameter and bush inner diameter ..................................................................................7

5.2.5 Flank bending ...................................................................................................................................8

5.2.6 Perpendicularity and parallelism of the spring eye ........................................................................8

5.3 Requirements for characteristic ......................................................................................................9

5.3.1 Spring rate ........................................................................................................................................9

5.3.2 Design camber..................................................................................................................................9

5.3.3 Fatigue ..............................................................................................................................................9

5.4 Requirements for manufacturing .....................................................................................................9

5.4.1 Hardness ...........................................................................................................................................9

5.4.2 Decarburization ................................................................................................................................9

5.4.3 Shot peening ....................................................................................................................................9

5.4.4 Presetting .......................................................................................................................................10

5.4.5 Lubricant and surface protection ..................................................................................................10

5.4.6 Surface conditions .........................................................................................................................10

6 Designation .....................................................................................................................................10

Annex A (normative) Test methods of the leaf springs ........................................................................... 11

© ISO 2012 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 18137-1

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a s ubject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 18137-1 was prepared by Technical Committee ISO/TC 227, Springs.iv © ISO 2012 – All rights reserved

---------------------- Page: 4 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 18137-1

Leaf springs — Part 1: Technical requirements and test

methods

1 Scope

This International standard specifies the technical requirements and test methods for leaf springs.

This International Standard is applicable to leaf springs for road vehicle (hereinafter simply “springs”). The leaf

springs for other vehicle may refer to this International standard.2 Normative references

The following referenced documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 683-14, Heat-treatable steels, alloy steels and free-cutting steels — Part 14: Hot-rolled steels for

quenched and tempered springsISO 3887, Steels — Determination of depth of decarburization

ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method

ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method

ISO 16249, Springs — Symbols

ISO 18265, Metallic materials — Conversion of hardness values

ISO 26909, Springs — Vocabulary

ISO 26910-1, Springs — Shot peening — Part 1: General procedures

3 Terms and symbols

3.1 Terms

For the purposes of this document, the terms given in ISO 26909 and Table 1 apply.

3.2 Symbols and unitsFor the purposes of this document, the symbols and units given in ISO 16249 and Table 1 apply.

© ISO 2012 – All rights reserved 1---------------------- Page: 5 ----------------------

ISO/DIS 18137-1

Table 1 — Terms, symbols and units

Term Symbol Unit Meaning

Spring end width b Width of the spring eye or sliding end

Assembled spring mm

b Width of the assembly in the range of U-clamping

width

Perpendicular distance from the surface where tensile stress

is generated in use, of the uppermost leaf at the centre pin or

Camber C the centre bolt, to the straight line connecting the centers of

both eyes or connecting the load-supporting points of the

spring

Free camber C mm Camber when free or at zero load

Design camber mm Camber under design (nominal) load

Eye inner diameter d Inner diameter of the spring eye

Eye bush inner mm

Inner diameter of the spring eye bush

diameter

Load N Total spring force

Design load F N Design (nominal) load of the spring

F N

Maximum test load Maximum test force of the spring

max,t

Height mm The overall height of the spring

Free height H mm Height when free or at zero load

Design height H mm Height under design (nominal) load

Span l mm Distance between the load-supporting points of the spring

Free Span mm Span when free or at zero load

Fixed half span l mm Length of the span between the fixed end and the centre

Length of the span between the load-supporting points of the

Straight span l mm

spring when the first leaf is straight

Fixed half straight Length of the span between the fixed end and the centre

l mm

ST,A

span when the first leaf is straight

Spring rate N/mm Force divided by one unit of deflection of the spring

Change of the vertical position of the centre pin or the centre

Deflection mm bolt against the line connecting the centers of both eyes or

connecting both load-supporting points of the spring

Design deflection mm The deflection under the design load

Maximum test

mm The deflection under the maximum test load

max,t

deflection

Flank bending mm Side bending deformation of the leaf

2 © ISO 2012 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/DIS 18137-1

4 Spring types

The most common spring types are shown in the following.

Figure 1 — Multi-leaf spring with eyes

(a)

(b)

Figure 2 — Parabolic spring with eyes

© ISO 2012 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO/DIS 18137-1

Figure 3 — Multi-leaf spring with one eye and one sliding end

Figure 4 — Parabolic spring with one eye and one sliding end

Figure 5 — Multi-leaf spring with sliding ends

4 © ISO 2012 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 18137-1

Figure 6 — Parabolic spring with sliding ends

Figure 7 — Two-stage progressive multi-leaf spring with helper spring

Figure 8 — Two-stage progressive parabolic spring with helper spring

Figure 9 — Two-stage rate parabolic spring with auxiliary spring

© ISO 2012 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO/DIS 18137-1

Figure 10 — Progressive (rate) spring

5 Technical requirements

5.1 Materials

Unless otherwise agreed by the purchaser and the supplier, the springs should be made from the hot rolled

spring flat bar conforming to ISO 683-14.5.2 Tolerances of spring dimensions and shapes

5.2.1 Span

The tolerances of the straight span and the fixed half straight span should be in accordance with Table 2.

Table 2 — Tolerances of spanDimensions in millimetres

Fixed half straight span, l

Straight span, l

ST,A

Tolerances Tolerances

Range Range

Type 1 Type 2 Type 1 Type 2

l r 600

l r 1200 ± 3,0 ± 3.5 ± 1,5 ± 2,0

ST,A

1200 < r 1600 ± 3,0 ± 5.0 600 < l r 800

l ± 1,5 ± 2,5

ST,A

1600 < r 2000 ± 3,0 ± 6,0 800 < l r 1000 ± 1,5 ± 3,0

ST,A

l > 2000 ± 4,0 ± 6,5 l > 1000 ± 2,0 ± 3,5

ST ST,A

5.2.2 Assembled spring

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.