ISO 18939:2013

(Main)Imaging materials — Digital hard copy for medical imaging — Methods of measuring permanence

Imaging materials — Digital hard copy for medical imaging — Methods of measuring permanence

ISO 18939:2013 establishes test methods for measuring the stability of photographic films intended for storage of medical records. It is applicable to greyscale images on films for use in transmission mode that are based on thermally processed materials (photothermography, thermography, microcapsule) or created by inkjet printing. Thermally processed materials have a base of safety polyester [poly (ethylene terephthalate)] and work predominantly with silver behenate salts dispersed in non-gelatinous emulsions or dye-based microcapsule emulsions that are thermally processed to produce a black-and-white image. In inkjet printing ink droplets are jetted onto a film with an ink-receiving layer to produce a greyscale image. ISO 18939:2013 does not cover wet-processed black-and-white films or black-and-white paper. It is not applicable to medical colour images or colour prints created by colour inkjet or dye diffusion thermal transfer (D2T2). Neither does it cover medical greyscale images printed on reflective materials for referral purposes or filmless systems such as picture archiving and communication systems (PACS) in medical imaging. ISO 18939:2013 requires the arbitrary choice of "illustrative end points" for changes in colour and perceived contrast to depict quantifiable changes due to physical ageing. Extrapolations based on ?illustrative end points' do not have any proven diagnostic or clinical relevance due to the lack of corresponding statistically significant scoring by radiologists.

Matériaux pour l'image — Photocopie numérique pour imagerie médicale — Méthodes de mesure de la permanence

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18939

First edition

2013-11-01

Imaging materials — Digital hard copy

for medical imaging — Methods of

measuring permanence

Matériaux pour l’image — Photocopie numérique pour imagerie

médicale — Méthodes de mesure de la permanence

Reference number

ISO 18939:2013(E)

©

ISO 2013

---------------------- Page: 1 ----------------------

ISO 18939:2013(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 18939:2013(E)

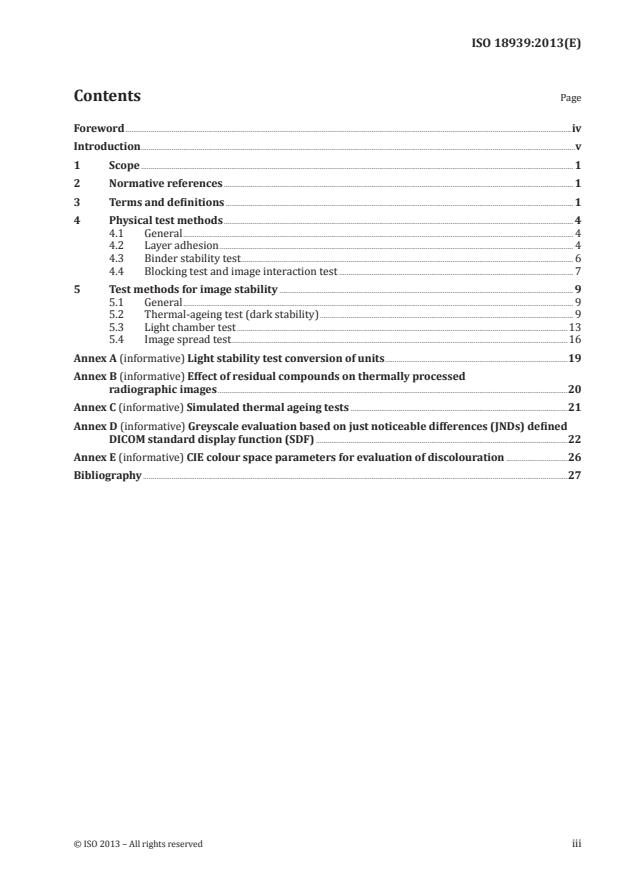

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Physical test methods . 4

4.1 General . 4

4.2 Layer adhesion . 4

4.3 Binder stability test . 6

4.4 Blocking test and image interaction test . 7

5 Test methods for image stability . 9

5.1 General . 9

5.2 Thermal-ageing test (dark stability) . 9

5.3 Light chamber test .13

5.4 Image spread test .16

Annex A (informative) Light stability test conversion of units .19

Annex B (informative) Effect of residual compounds on thermally processed

radiographic images .20

Annex C (informative) Simulated thermal ageing tests .21

Annex D (informative) Greyscale evaluation based on just noticeable differences (JNDs) defined

DICOM standard display function (SDF) .22

Annex E (informative) CIE colour space parameters for evaluation of discolouration .26

Bibliography .27

© ISO 2013 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 18939:2013(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information.

The committee responsible for this document is ISO/TC 42, Photography.

iv © ISO 2013 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 18939:2013(E)

Introduction

This International Standard prepared by ISO TC 42, WG 5 provides information for measuring the image

stability and other relevant properties of medical dry hard copy films with greyscale images made with

photothermographic, thermographic, and microcapsule type materials or with inkjet printing. Medical

colour images and prints on reflective material for referral purposes are not covered.

Medical dry hard copy films are employed widely for digitally recording medical images in general

radiography and mammography, because of the systems’ simplicity, flexibility, ease of use, and attendant

environmental advantages. First realizations of medical dry hardcopy systems entered the market

together with CR and DR modalities in the 1990s, starting with photothermographic, thermographic,

and microcapsule type materials. Recently, also inkjet based systems were also available. Dry hard copy

systems gained through its one-step dry processing method which obviates the need for film processing

equipment and liquid processing solutions and provides a significant saving in capital and labour costs.

Thermally processed dry hard copy films use osynthetic polymers, e.g. poly (vinylbutyral), poly

(vinyl alcohol), and poly (styrene butadiene) as binders for image forming silver clusters, instead of

gelatine being used in wet processed AgX films. This renders the binder more inert to moisture and

its deleterious effects, including oxidation. The support for thermally processed dry hard copy films is

[1][2][3][4][5][6]

normal, photographic grade PET [poly (ethylene terephthalate) safety film.

A disadvantage of thermally processed dry hard copy images is their greater potential instability caused

by the presence of unused chemicals after image formation; these are not removed by liquid processing

solutions as with conventional silver halide films. Consequently, the potential for formation of excessive

fog exists throughout the life of the thermally processed dry hard copy film. Such degradation of image

quality has occasionally been observed in the course of prolonged exposure to ambient illumination

or storage under high temperature or, most frequently, due to unintended over-exposure to light and

heat in a reader-printer (view box). Also, in case of a fire in the storage area or near a vault or safe,

the temperature sometimes increase sufficiently high to cause image degradation, even though the

temperature used for generating thermally processed dry hard copy images range well above 100 °C.

These images are considerably stable under normal user and storage conditions as well as on accelerated

[7][8][9]

ageing studies ). Hence, thermally processed dry hard copy films do not fall within the provisions

of ISO 18901 that apply to chemical fixation.

Inkjet based dry hard copy images may also be susceptible to temperature, humidity and light depending

on the details of the technical details of the inkjet printing system, its type of ink (e.g. aqueous, solvent

or wax based), the colorants (dye or pigment) and the type of ink receiver layers (porous, swellable, etc.)

of the hard copy film.

2

General radiographs are normally viewed on light boxes at a luminance level of 2 000 to 4 000 cd/m ,

[24][25]

whereas according to American College of Radiology (ACR) recommended practices, mammograms

2

and clinical quality reviews are viewed at a luminance of at least 3 000 cd/m or higher depending on

the modality. In addition, all mammograms and mammogram test images are required to be masked

completely during diagnostic inspection, so that no light directly emitted by the light box surface can

reach the observer’s eyes. The recommended level of intensity of surrounding illumination in that viewing

2

situation is below 10 cd/m . In practice, light box outputs and surrounding illumination conditions do

vary considerably and, therefore, this standard requires use of a light chamber which permits close

control of all illumination parameters, temperature, relative humidity and duration of exposure.

Everyone concerned with the preservation of records on radiographic film understands that specifying

the chemical and physical characteristics of the material does not, by itself, ensure that the records

will not deteriorate. It is also recognized that enclosure materials used to make radiographic envelopes

effects the preservation quality of records It is also essential to provide the correct storage temperature

and humidity, and protection from the hazards of fire, water, fungus, and certain atmospheric pollutants.

These aspects are considered in pertinent International Standards for storage of films, for example,

[16] [17]

ISO 18902 and ISO 18911.

© ISO 2013 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 18939:2013(E)

Imaging materials — Digital hard copy for medical imaging

— Methods of measuring permanence

1 Scope

This International Standard establishes test methods for measuring the stability of photographic

films intended for storage of medical records. It is applicable to greyscale images on films for use

in transmission mode that are based on thermally processed materials (photothermography,

thermography, microcapsule) or created by inkjet printing. Thermally processed materials have a

base of safety polyester [poly (ethylene terephthalate)] and work predominantly with silver behenate

salts dispersed in non-gelatinous emulsions or dye-based microcapsule emulsions that are thermally

processed to produce a black-and-white image. In inkjet printing ink droplets are jetted onto a film with

an ink-receiving layer to produce a greyscale image.

This International Standard does not cover wet-processed black-and-white films or black-and-white

paper. It is not applicable to medical colour images or colour prints created by colour inkjet or dye

diffusion thermal transfer (D2T2). Neither does it cover medical greyscale images printed on reflective

materials for referral purposes or filmless systems such as picture archiving and communication

systems (PACS) in medical imaging.

This International Standard requires the arbitrary choice of “illustrative end points” for changes in

colour and perceived contrast to depict quantifiable changes due to physical ageing. Extrapolations

based on ‘illustrative end points’ do not have any proven diagnostic or clinical relevance due to the lack

of corresponding statistically significant scoring by radiologists.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 5-2, Photography and graphic technology — Density measurements — Part 2: Geometric conditions for

transmittance density

ISO 5-3, Photography and graphic technology — Density measurements — Part 3: Spectral conditions

ISO 18907, Imaging materials — Photographic films and papers — Wedge test for brittleness

ISO 18924, Imaging materials — Test method for Arrhenius-type predictions

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

adherography

imaging technology utilizing a high intensity laser beam to form a positive carbon image through

differential thermal adhesion

Note 1 to entry: This process involves fusion of a laser sensitive, carbon-containing layer with the final imaging

layer in exposed areas, followed by controlled peeling, which removes the unexposed portion. The positive image

is then made durable and permanent by the application of a transfer coat.

© ISO 2013 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 18939:2013(E)

3.2

microcapsule

imaging technology in which heat-responsive microcapsules containing dye precursors are thermally

rendered to develop a dye image

Note 1 to entry: Heat-responsive microcapsules containing dye precursors are dispersed together with a

development emulsion on a polyester support. Application of computer-modulated heat that matches the density

pattern of a digital image renders the walls of the microcapsules differently permeable. The varying amounts

of developer, which penetrate the capsule walls, produce corresponding differences in dye image density. The

capsule walls revert to their impermeable state on cooling and provide protection against dye formation and dye

degradation under normal storage conditions.

3.3

phase change solid inkjet

imaging technology based on modulated deposition of micro-droplets of non-aqueous, waxy inks on a

microcellular surface of a layer coated on a polyester support

Note 1 to entry: Four shades of neutral ink are used to obtain the wide grey scale density range required for

medical images. The melting point of the ink is considerably above ambient temperature, ensuring image stability

under normal storage conditions.

3.4

photothermography

imaging technology based on thermal development of a light-induced latent image in dispersed silver salts

Note 1 to entry: The process involves a polymeric layer containing light sensitive silver halide crystals, light

insensitive silver behenate crystallites, silver soaps and a reducing agent coated on a polyester support. A latent

image formed by light exposure of the silver halide crystals catalyses an oxidation-reduction reaction between

the silver behenate and the reducing agent upon heating above 120 °C. This yields a metallic silver image by

physical development.

3.5

thermography

imaging technology based on image-wise thermal modulation and development of dispersed silver salts

Note 1 to entry: The process utilizes a polymeric layer containing a light-insensitive organic silver salt, a reducing

agent and a stabilizer, coated on a polyester support. Reduction of the organic silver salt by the reducing agent

accelerated by heat (100 °C–200 °C) yields a metallic silver image whose densities are controlled by the adjustable

temperature of print head elements. The integrity of the silver image under normal storage conditions is secured

by stabilization of the unused silver salt.

3.6

aqueous inkjet

imaging technology involving image formation with an aqueous ink by a modulated deposition of micro-

droplets on the surface of an ink absorbing layer coated on a polyester support

Note 1 to entry: Black-and-white and colour images can be produced by suitable selection of inks.

3.7

just noticeable difference levels

jnd-levels

measure of the non-linear response of the visual system to luminance stimuli defined as a table of

2

ascending photometric luminance levels (between 1 and 10 000 cd/m ), which are perceived as

[20]

equidistant with the smallest perceivable difference (“just noticeable difference”) between them

3.8

jnd-contrast

Δjnd

numerical difference between the jnd-levels of two neutral patches on a radiographic film for a given

viewing situation (intensity of light box and ambient light intensity), which is used as measure of

perceived contrast between the two patches

2 © ISO 2013 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 18939:2013(E)

3.9

change in jnd-contrast

(Δjnd (t)/Δjnd(0)) – 1

measure of relative change in perceived contrast between two neutral patches — for example in the

course of a stability test: Δjnd(t) / Δjnd(0) – 1, i.e. [(jnd-contrast after treatment)/(jnd-contrast before

treatment)] – 1

3.10

colour changes

Δa*, Δb*

differences in the CIE colour coordinates a* and b*, e.g. in the course of incubation of dry hardcopy film

3.11

endpoints

set of numerical values defining those changes in colour (Δa*, Δb*) and jnd-contrast [(Δjnd(t)/Δjnd(0))

– 1], for given reference visual density (D ) at which time to failure is evaluated in the course of

vis

thermal-stability and light-stability tests in order to produce Arrhenius extrapolation plots following

the Arrhenius test method described in ISO 18924

3.12

diagnostic endpoint

set of endpoints, for which changes in colour (Δa*, Δb*) and jnd-contrast [(Δjnd(t)/Δjnd(0)) – 1] for given

visual density (D ), have been correlated with loss of the materials’ diagnostic function based on

vis

statistically validated psychophysical scoring by radiologists

Note 1 to entry: At the time of writing this standard document insufficient data was available to specify diagnostic

end points that could be judged as “relevant or prohibitive” from the standpoint of medical diagnostics. Diagnostic

end points need a correlation with judgments or scores by radiologists, for which a statistically relevant set

of psychometric data for a given medical application or modality is needed. Diagnostic end points depend on

a variety of factors, amongst which are — nonexclusively — type of modality, pathology under investigation,

method of image processing, printer settings and density range of the medical image.

3.13

illustrative endpoints

set of arbitrarily defined endpoints for changes in colour (Δa*, Δb*), and jnd-contrast Δjnd(t)/Δjnd(0) – 1

for a given reference visual density D , at which time to failure is evaluated in the course of thermal

vis

stability tests

Note 1 to entry: Arrhenius extrapolations based on illustrative end points do not have any proven diagnostic

or clinical relevance due to the lack of corresponding psycho-visual data. For diagnostically relevant Arrhenius

extrapolations a set of diagnostic end points would be necessary.

3.14

film base

plastic support for the emulsion and backing layers

3.15

emulsion layer

image or image-forming layer of photographic films, papers and plates

3.16

safety poly (ethylene terephthalate) base

polyester film base composed mainly of a polymer of ethylene glycol and terephthalic acid

3.17

processed dry hard copy film

dry hard copy film on which a (test) image has been written by its corresponding printer (in analogy to

the wet processing of conventional AgX based film)

© ISO 2013 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 18939:2013(E)

4 Physical test methods

4.1 General

This section describes tests for layer adhesion (4.2), binder stability (4.3) as well as blocking and image

interaction (4.4).

4.2 Layer adhesion

4.2.1 General

Layer adhesion failure is tested under two conditions, namely for tape-stripping (4.2.2) and humidity

cycling (4.2.3).

4.2.2 Tape-stripping adhesion test

4.2.2.1 General

The results of the tape-stripping test may depend upon the adhesive tape used if the bonding force

between the adhesive tape and the particular film surface under test is not sufficiently high. For this

reason, a minimum bonding force is specified for this test. This bonding force shall be determined by

applying the adhesive tape to the film surface in the same manner as described in the tape-stripping

test. The tape shall be rapidly peeled back from the film surface at an angle of approximately 180°. The

peel back force required to separate the tape from the film shall be measured by a suitable device such

as a strain gauge or spring scale capable of reading the maximum force used. A bonding force of at least

0,9 N per millimetre of tape width is required.

4.2.2.2 Specimen preparation

Although the dimensions of the processed film specimen are not critical, one dimension shall be at least

150 mm to allow proper handling during the test. Four specimens shall be used for the emulsion surface

and four specimens for the backing layer, if present.

4.2.2.3 Conditioning

All specimens shall be conditioned at 23 ± 2 °C and at 50 ± 5 % relative humidity for at least 15 h. This

can be accomplished by means of an air-conditioned room or an air-conditioned cabinet. The specimens

shall be supported in such a way as to permit free circulation of the air around the film and the linear air

velocity shall be at least 150 mm/s.

4.2.2.4 Procedure

The film specimens shall not be removed from the conditioning atmosphere for testing. Apply a strip of

pressure-sensitive, plastic-base adhesive tape about 150 mm long to the surface of the processed film.

Press the tape down with thumb pressure to ensure adequate contact, leaving enough tape at one end to

grasp. No portion of the tape shall extend to the edges of the film specimens or extend to film notches.

In order to facilitate physical ageing, the adhesive-taped film specimens shall be kept for 16 h prior to

stripping. Hold the specimen firmly on a flat surface and remove the tape rapidly from the film surface.

This shall be accomplished by peeling the tape back on itself and pulling the end so that it is removed

from the film at an angle of approximately 180°.

4.2.2.5 Reporting of results

The processed film shall be examined for any evidence of removal of the emulsion layer or backing

layer, when tested.

4 © ISO 2013 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 18939:2013(E)

4.2.3 Humidity-cycling adhesion test

4.2.3.1 General

This test evaluates the sticking, blocking and delaminating of emulsion or backing layers or transference

of paper material to the film surface.

4.2.3.2 Specimen preparation

Two specimens of processed film shall be selected from an area of high density. The preferred specimen

size is 50 mm × 50 mm, or 50 mm × film width where the size of the film permits. However, dimensions

are not critical, provided all specimens are of uniform size and proper handling is possible.

4.2.3.3 Procedure

The procedures can be followed either with two separate humidity-temperature controlled ovens or

by using two glass desiccators as described below. The physical test conditions of temperature, relative

humidity and duration of the test shall remain the same in both procedures.

NOTE Films occasionally exhibit what appear to be small pinholes in the image after processing. These can

be caused by dirt or dust particles on the emulsion surface at the time the raw film is exposed and should not be

confused with holes or cracks in the emulsion layer. The existence of such clear spots in the image prior to humidity

cycling should be noted so that their presence does not lead to a false interpretation of adhesion weakness.

4.2.3.3.1 Humidity-temperature controlled oven method

Mount the test specimens in a specimen rack and place the rack inside the oven in such a way that the

specimens are freely exposed to the required conditioning atmosphere. Place the rack in a forced-air

circulating humidity and temperature controlled oven for 8 h at 50 ± 2 °C and 80 ± 5 % relative humidity.

After 8 h, place the specimens and specimen rack for 16 h in a second humidity and temperature

controlled oven maintained at 50 ± 2 °C and 11 ± 5 % relative humidity.

The sequence of time periods of 8 h at high relative humidity and 16 h at low relative humidity shall

constitute one cycle.

NOTE This can be easily accomplished by placing the specimens in the high relative humidity chamber in the

morning and in the low humidity chamber in the evening.

Each film specimen shall be subjected to 12 humidity cycles. After this, remove the film specimens from

the specimen rack and examine the emulsion and any backing layer for any evidence of peeling, flaking,

or cracking produced as a result of the humidity-cycling treatment (see 4.2.3). During an interruption

in the cycling procedure, the film specimens shall be kept at 50 ± 2 °C and 11 ± 5 % relative humidity.

4.2.3.3.2 Glass desiccator method

Two glass desiccators with saturated aqueous salt solutions are placed in an oven that is controlled at

50 ± 2 °C: In one dessicator a saturated solution of ammonium sulfate (NH ) SO in water is provided at

4 2 4

the bottom of the jar and in another dessicator a saturated solution of lithium chloride in water.

Ensure that the saturated solutions contain an excess of undissolved crystals at 50 °C. The undissolved

crystals shall be completely covered by a layer of saturated salt solution and the surface area of the

solution should be as large as practical. The jars with salt solution shall be kept in the oven at 50 ± 2 °C

for at least 20 h prior to use to ensure attainment of equilibrium. At 50°C, the atmosphere in the jar with

ammonium sulfate (NH ) SO will reach 80 % rV, representing the high relative humidity condition,

4 2 4

whereas the atmosphere in the jar with lithium chloride will reach 11 % rH, representing the low relative

[10][11]

humidity condition

NOTE 1 The relative humidity in the desiccator method is based on the normal vapour pressure of the salt

solution, but the relative humidity tolerance cannot be specified.

© ISO 2013 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 18939:2013(E)

Mount the test specimens in a specimen rack and place the rack in the first desiccator jar with the

saturated ammonium sulfate solution in such a way that the specimens are freely exposed to the

required conditioning atmosphere. After 8 h, place the specimens and specimen rack for 16 h in the

second desiccator jar with the saturated lithium chloride solution. Maintain both jars in the forced-air

circulating oven at 50 ± 2 °C.

The sequence of time periods of 8 h at high relative humidity and 16 h at low relative humidity shall

constitute one cycle.

NOTE 2 This can be easily accomplished by placing the specimens in the high relative humidity jar in the

morning and in the low humidity jar in the evening.

Each film specimen shall be subjected to 12 humidity cycles. After this, remove the film specimens from

the specimen rack and examine the emulsion and any backing layer for any evidence of peeling, flaking,

or cracking produced as a result of the humidity-cycling treatment (see 4.2.3). During an interruption in

the cycling procedure, the film specimens shall be kept at 50 ± 2 °C in the desiccator with the low relative

humidity (saturated Lithium Chloride solution).

4.2.4 Reporting of results

The film shall be examined under the magnification and lighting conditions that are normal for the

intended use of the product. The emulsion layer or backing layer of the processed film shall be examined

for layer sepa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.