ISO 11891:2012

(Main)Hot formed helical compression springs — Technical specifications

Hot formed helical compression springs — Technical specifications

This International Standard specifies the materials, shapes, spring characteristics, tolerances, manufacturing requirements and test methods for common helical compression springs, which are made from hot coiled round section steel bar, and then quenched and tempered (hereinafter simply "springs"). The following limit values apply to springs conforming to this International Standard: — free length: ≤ 900 mm; — spring index: 3 to 12; — slenderness ratio: 0,8 to 4; — active coils: ≥ 3; — spring pitch: D; — wire diameter: 8 mm to 60 mm; — mean diameter of coil: ≤ 460 mm. This International Standard is not applicable to coil springs with special performance requirements, such as railway and automotive suspensions.

Ressorts de compression hélicoïdaux formés à chaud — Spécifications techniques

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11891

First edition

2012-04-15

Hot formed helical compression

springs — Technical specifications

Ressorts de compression hélicoïdaux formés à chaud —

Spécifications techniques

Reference number

ISO 11891:2012(E)

©

ISO 2012

---------------------- Page: 1 ----------------------

ISO 11891:2012(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 11891:2012(E)

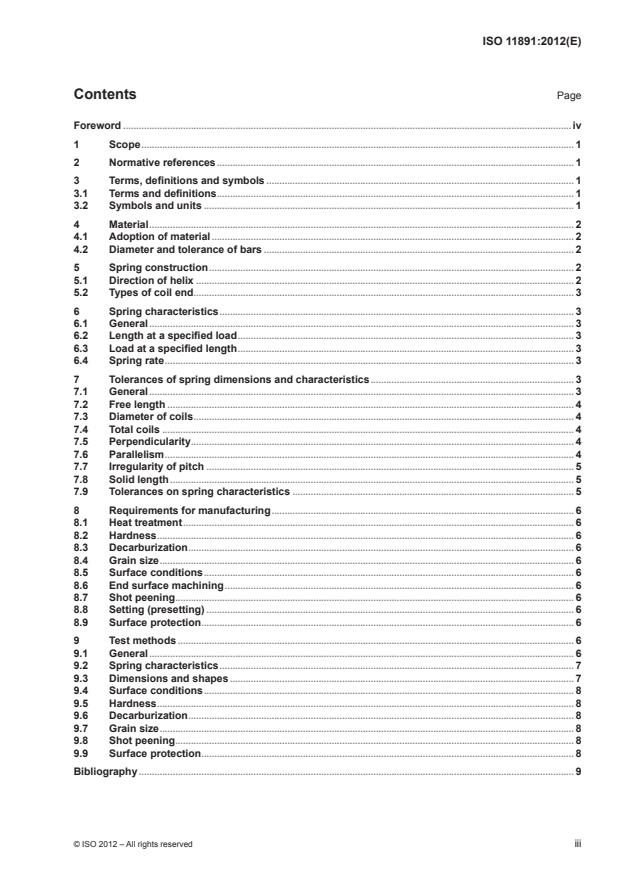

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and symbols . 1

3.1 Terms and definitions . 1

3.2 Symbols and units . 1

4 Material . 2

4.1 Adoption of material . 2

4.2 Diameter and tolerance of bars . 2

5 Spring construction . 2

5.1 Direction of helix . 2

5.2 Types of coil end . 3

6 Spring characteristics . 3

6.1 General . 3

6.2 Length at a specified load . 3

6.3 Load at a specified length . 3

6.4 Spring rate . 3

7 Tolerances of spring dimensions and characteristics . 3

7.1 General . 3

7.2 Free length . 4

7.3 Diameter of coils . 4

7.4 Total coils . 4

7.5 Perpendicularity . 4

7.6 Parallelism .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.